How Induction Heaters Streamline Metalworking and Assembly?

In the fast-paced world of modern manufacturing, efficiency, precision, and safety are paramount. One technology that has revolutionized metalworking and assembly processes is induction heating.

This method uses electromagnetic induction to heat materials rapidly and precisely, offering numerous advantages over traditional heating techniques. From automotive to aerospace, induction heating is streamlining operations across various industries.

What Is Induction Heating?

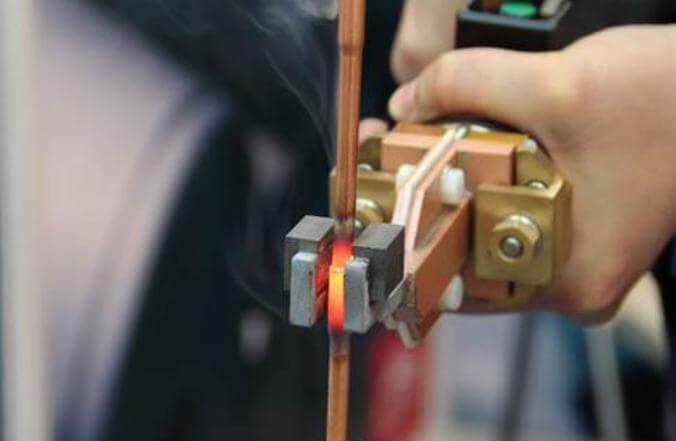

Induction heating is a non-contact process that utilizes electromagnetic fields to generate heat directly within a conductive material. An alternating current passes through a coil, creating a magnetic field that induces eddy currents in the workpiece.

These currents generate heat due to the material’s resistance, allowing for rapid and localized heating without direct contact.

This method contrasts with traditional heating techniques, which often rely on external heat sources and can result in uneven heating and longer processing times. Induction heating offers a more controlled and efficient alternative.

Electromagnetic Process in Induction Heating

Induction heating leverages electromagnetic fields to efficiently heat metal. When a metal part is placed inside an induction coil, the coil generates a fluctuating magnetic field. This changing field induces eddy currents within the metal. As the metal resists the flow of these currents, the electrical energy is converted into heat. This process allows the metal to heat up quickly and uniformly.

One of the key advantages of induction heating is its precise control over the heating process. You can target specific areas of the metal, ensuring that only the desired section is heated. This capability is particularly beneficial for applications such as hardening, melting, and joining metals, where accuracy and efficiency are essential.

Advantages of Induction Heating in Metalworking and Assembly

Speed and Efficiency

Induction heating is known for its rapid heating capabilities. Components can reach desired temperatures in seconds, significantly reducing processing times. This speed translates to increased production rates and improved overall efficiency in manufacturing processes.

Precision and Control

The ability to heat specific areas of a workpiece with high precision is a significant advantage of induction heating. This localized heating minimizes the risk of damaging surrounding areas and allows for more accurate processing, which is crucial in industries where tight tolerances are required.

Energy Efficiency

Induction heating is highly energy-efficient. Unlike traditional methods that heat the entire environment, induction heating directly heats the material, reducing energy consumption. Some systems can achieve energy efficiencies of up to 90%, leading to lower operational costs and a smaller environmental footprint.

Safety

Since induction heating does not involve open flames or hot surfaces, it presents a safer alternative to conventional heating methods. This reduction in fire hazards is particularly beneficial in environments where safety is a top priority.

Reduced Material Distortion

The rapid and localized heating provided by induction heating reduces the thermal gradients within a workpiece, minimizing the risk of warping or distortion. This is especially important in precision manufacturing where material integrity is critical.

Applications of Induction Heating in Metalworking and Assembly

Heat Treatment

Induction heating is extensively used in heat treatment processes such as hardening, annealing, and tempering. The ability to control heating rates and temperatures precisely allows for the modification of material properties to meet specific requirements.

Brazing and Soldering

Induction heating provides a clean and efficient method for brazing and soldering metal components. The localized heating ensures that only the joint area reaches the necessary temperature, leading to strong and reliable bonds without affecting the surrounding material.

Shrink Fitting

In assembly processes, induction heating is used to expand components by heating them, allowing for easy insertion over another part. Once cooled, the components contract, creating a tight interference fit. This method is widely used in bearing installations and other precision assemblies.

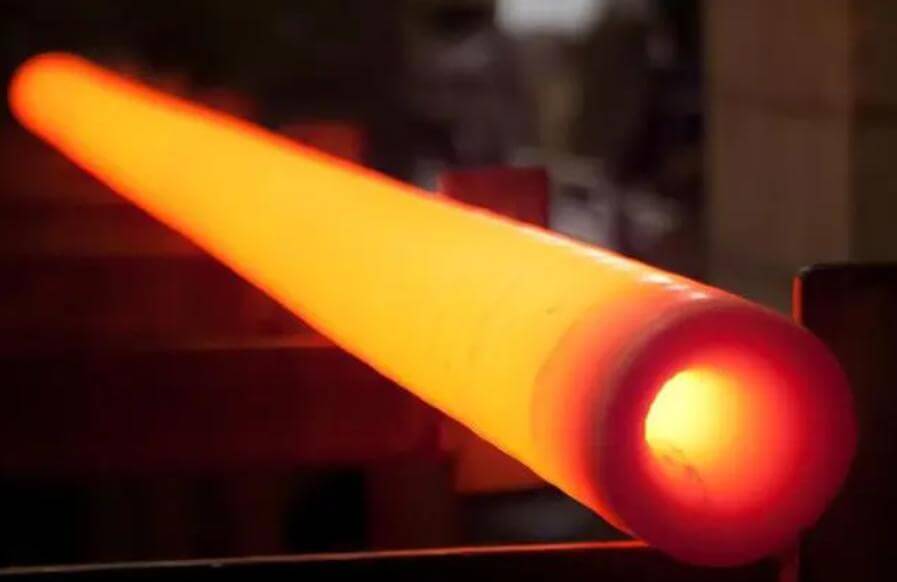

Forging and Forming

Induction heating is employed to heat metals to forging temperatures, facilitating easier shaping and forming. The uniform and rapid heating ensures consistent material properties and reduces the risk of defects during the forging process.

Surface Hardening

Induction hardening is a process where specific areas of a workpiece are heated and then rapidly cooled to increase surface hardness. This technique is commonly used for components like gears and shafts that require wear resistance.

Choosing the Right Induction Heating System

Selecting the appropriate induction heating system depends on several factors, including:

Material Type: Different materials respond differently to induction heating. It’s essential to choose a system compatible with the specific material being processed.

Component Size and Geometry: The size and shape of the workpiece influence the choice of induction coil design and power requirements.

Production Volume: High-volume production may benefit from automated induction heating systems, while smaller batches might be suited for portable or manual units.

Process Requirements: Specific processes like brazing, hardening, or shrink fitting have unique heating requirements that should be considered when selecting a system.

Future Trends in Induction Heating

The field of induction heating continues to evolve with advancements in technology.

Future trends include:

Integration with Automation: Incorporating induction heating into automated production lines for seamless integration and increased efficiency.

Advanced Control Systems: Development of more sophisticated control systems that offer real-time monitoring and adjustments to optimize heating processes.

Energy Recovery Systems: Implementation of systems that recover and reuse heat energy, further enhancing energy efficiency.

Portable Solutions: Development of more compact and portable induction heating units for on-site applications and maintenance tasks.

Conclusion

Induction heating has proven to be a transformative technology in metalworking and assembly processes. Its speed, precision, energy efficiency, and safety benefits make it an invaluable tool in modern manufacturing.

As industries continue to demand higher performance and lower costs, induction heating stands poised to play a pivotal role in shaping the future of metalworking and assembly operations.

KEXIN’s induction melting furnace has higher thermal efficiency and lower energy consumption. They can produce a mild metal bath mixture, mixing a uniform alloy at a constant and uniform temperature. For these reasons, this type of furnace is the first choice for induction melting. Kexin products can flexibly meet all customer requirements.

Can we help you?

Whatsapp

Whatsapp