120KW Electromagnetic Heating Equipment

What are 120KW High Frequency Bearing Induction Heater Advantages?

120KW high-frequency bearing induction heater does not need to heat the workpiece as a whole, but can selectively heat the parts, so as to achieve the purpose of reducing power consumption, and the deformation of the workpiece is not obvious. The fast heating speed can make the workpiece reach the required temperature in a short time or even within 1 second. As a result, the surface oxidation and decarburization of the workpiece are relatively small, and most workpieces do not require gas protection.

The high-frequency bearing induction heater can adjust the surface hardening layer by adjusting the working frequency and power of the equipment as needed. As a result, the hardness, strength, and toughness of the hardened layer are relatively high. After the heat treatment by the induction heating method, the toughness area of the workpiece under the surface hard layer becomes thicker, and the compressive internal stress is also improved, thereby making the workpiece more resistant to fatigue and fracture. The induction heating machine is easy to install on the production line, easy to realize mechanization and automation, easy to manage, and can effectively reduce transportation, save manpower, and improve production efficiency.

High-frequency bearing induction heaters can realize multiple purposes on one machine. It can complete the heat treatment process, such as quenching, tempering, welding, smelting, thermal assembly, thermal disassembly, and thermal forming, easy to operate, and can be started or stopped at any time. And no preheating is required. It can be operated manually, semi-automatically, and fully automatically; it can work continuously for a long time, or a high-frequency heating machine can be used randomly when in use.

KEXIN’s high frequency bearing induction heater advocated by the state has high electric energy utilization, environmental protection and energy saving, safety and reliability, and good working

120KW electromagnetic heating equipment can improve the working environment, increase production efficiency and reduce production costs. The machines have the ability to guaranty product quality, producing fire-free safety.

| Electromagnetic Heating Equipment | |

| Model | KX-120 |

| Power | 120KW |

| Voltage | Three phase 380V |

| Heating Area | 1200-1600mm² |

| Equipped Copper-core cable | ≥50mm² |

| Current | 180A |

| Frequency | 11-13KHz |

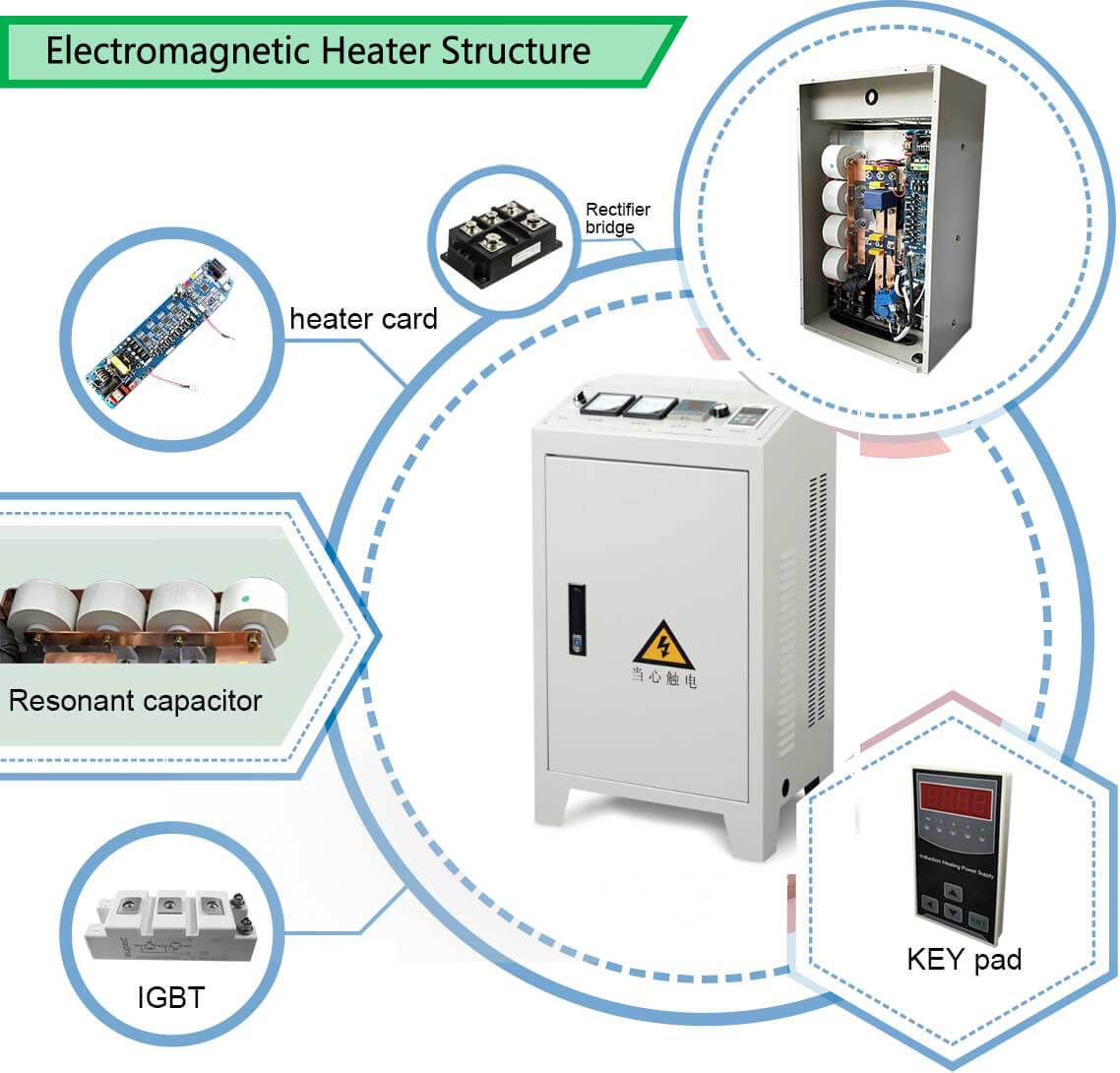

Electromagnetic heating equipment offers a controllable and localized method of heat without contact with the parts (components) being heated. The heat of the electromagnetic heating equipment is generated by inducing an alternating magnetic field into electrically conductive materials. Electromagnetic heating equipment is very low cost to run and normally creates significant cost savings versus other traditional process heating technologies.

The heating method of the electromagnetic heating equipment is to transfer heat to the barrel by contact conduction. Only the heat close to the inner side of the barrel surface can be transferred to the barrel. In this way, most of the heat on the outside is lost to the air, resulting in heat conduction loss and causing the ambient temperature to rise.

Electromagnetic heating technology uses the principle of electromagnetic induction to make the metal barrel itself heat up, and a certain thickness of heat insulation material can be wrapped on the outside of the barrel according to the specific situation, which greatly reduces the heat loss and improves the thermal efficiency. Therefore, the power saving effect is very significant, up to 30% to 75%.

Because the electromagnetic heating coil itself does not generate heat, and is made of insulating materials and high-temperature cables, there is no problem of shortening the service life of the resistance wire of the original electric heating coil due to oxidation under high temperature. It has the advantages of long service life, fast heating rate, no need for maintenance, etc., which reduces maintenance time and reduces costs. It has been used by a large number of plastic products, building materials, pipelines and other companies, greatly reducing the production costs of enterprises.

What can Electromagnetic heating equipment do?

It offers a widely range of applications for industrial heating in the Plastics, Chemical, Pharmaceutical, Food, Printing, Construction, HVAC, Heat Treatment, Smelting And Other Industries Energy Saving. for example: plastic inject molding machine, oil heating, hot water, metal heating, hot air, diffusion pumps heating and other custom applications.

Does electromagnetic heating equipment cause consume much energy?

Compared with traditional heater, the efficiency of electric of electromagnetic heating unit to heat conversion is up to 98%. It’s energy saving and environment-friendly.

Application:

- Plastic and rubber industry, such as: plastic film blowing machine, wire drawing machine, injection molding machine, granulator, rubber extruder, vulcanizer, cable production extruder, etc.

- Pharmaceutical and chemical industry, such as: pharmaceutical infusion bags, plastic equipment production line, chemical industry liquid heating pipeline, etc.

- Energy and food industry, such as: heating of crude oil pipeline; food machinery, such as: super cargo machine and other equipment that requires electric heating.

- High-power commercial electromagnetic stove movement.

- Building materials industry, such as: gas pipe production line, plastic pipe production line, PE plastic hard flat net, geonet unit, automatic hollow molding machine, PE honeycomb board production line, single and double wall corrugated pipe extrusion production line, composite air cushion film unit, PVC hard pipe, core layer foam pipe production line, PP extrusion transparent sheet production line, extrusion polystyrene foam pipe, PE winding film unit.

- Drying and heating in printing equipment.

- Heating in other similar industries.

REQUEST A QUOTE

Do you need help with choosing our products?

Fill out this form to get in touch with us.

Whatsapp

Whatsapp