40KW Handheld Type Induction Welding Machine

The 40KW handheld type induction welding machine offers several key features that make it a powerful and versatile tool for various industrial applications.

Product Features

Model: KX-40

High Power Output

Precision Heating

Fast Heating Time

Versatile Applications

Low Maintenance

PRODUCT DETAILS

Supported by a team of industry experts, we provide a wide range of handheld induction welding machine to our clients. These heaters are meticulously designed and precision-engineered for enhanced functionality and long-lasting performance. Additionally, each unit undergoes rigorous testing across various quality parameters to ensure a flawless product delivery to our clients.

| Handheld Type Induction Welding Machine | |

| Model | KX-40 |

| Rated Power Output | 40KW |

| Maximum Apparent Power | 40KVA |

| Frequency Range | 10-60KHz |

| Main Extension Cable Length | 5m |

| Voltage | 380V+/-10% |

| Frequency | 50/60Hz |

| Rated Current | 40A |

| Maximum Current | 64A |

| Host Size | 660*580*770 |

| Net Weight | 70KG |

| Protection Level | IP42 |

| Packing Method | Wooden Box |

Portable induction heaters are ideal for industrial heating applications, especially for welding various types of pipes. They are commonly used by manufacturers and suppliers of pipes, such as copper pipes for air conditioners, lathe tools, and stainless steel pipes for furniture. Their compact and portable design makes them easy to operate. In addition, their main advantages include improved product quality, longer product life, and reduced energy consumption.

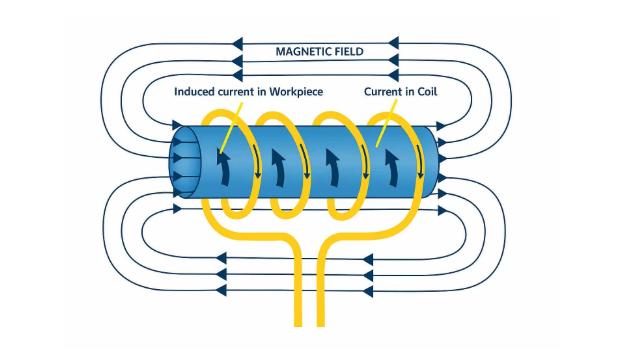

How Does This Portable Induction Brazing Machine Works?

Portable induction brazing equipment works by heating an electrically conductive object, typically metal, through electromagnetic induction. The heat is generated by the eddy currents induced within the material.

What Does The Induction Heater Consists of?

The high-frequency induction copper brazing machine consists of an electromagnet and an electronic oscillator. It passes high-frequency alternating current (AC) through the electromagnet, creating a rapidly alternating magnetic field that penetrates the object and induces eddy currents inside the conductor.

An induction heating system includes three key components: an AC power source, an induction coil, and the workpiece (the material to be heated). The power source sends AC through the coil, generating a magnetic field. When the workpiece is placed within the coil, the magnetic field induces eddy currents in the material. As a result, the handheld induction brazing machine generates precise, clean, and localized heat without direct contact between the coil and the workpiece.

Portable Induction Heating Machine Main Parts

Control Method: Digital embedded control software.

Main Chip: ARM STM32.

Chip Speed: 72MHz

Working Mode: Manual mode, automatic mode, and temperature control mode.

Current Heating Setting: 5 sections (can be extended to 32).

Number of Working Parameter Storage: 10 pcs/mode.

Display Screen: 3.5 inches True Color display screen, resolution ratio 320*240.

Communication & Start-up Interface: DB-9 and 4 cores air plug.

Bus Access: RS485 (recommended), Profibus (optional), CANbus (optional).

Trial Function Time: 200 hours. (While the trial function enables, the device will be locked down when it reaches the setting time.).

Widely Used in Many Different Applications

The 40KW Handheld Induction Welder is a powerful and versatile tool for a wide range of applications. This efficient and portable device provides high-frequency induction heating, making it ideal for welding a variety of materials such as steel, copper and alloys. Its compact design makes it easy to operate in tight spaces, and its powerful power output ensures precise and high-quality welds.

The 40KW power is ideal for industrial applications, including pipes, metal parts and components in the automotive, aerospace and manufacturing industries. Not only does this device improve welding accuracy, it also reduces processing time and improves energy efficiency, making it a reliable choice for a variety of welding tasks.

KEXIN Handheld Type Induction Welding Machine

What Is The Advantages of Handheld Type Induction Welding Machine ?

Advanced Technologies

High Frequency Induction Brazing Equipment utilizes advanced MOS and IGBT frequency conversion control technologies to enable automatic frequency tracking.

Alarm Interface Induction Brazing Copper Pip

The equipment features approximately ten types of fault protection, including over-current, over-voltage, water shortage, and phase loss, ensuring enhanced reliability and durability.

Memory Card Type

The industrial-grade SD card, capable of storing over 360 days of processing and alarm data, is available as a separate purchase and includes matching functionality.

Data Analysis Software

The handheld induction brazing machine is compact and lightweight, making it easy to hold, store, and operate. Its fully integrated digital control system offers various protective features, fast operation, a low failure rate, and a long lifespan.

RELATED QUESTIONS

How does the induction heating process work in this machine?

The machine generates an electromagnetic field that induces currents in the workpiece, rapidly heating the material to the required welding temperature without direct contact, ensuring clean, precise, and efficient welds.

Is the 40KW Handheld Type Induction Welding Machine easy to use?

Yes, the machine is designed for ease of use, with intuitive controls and a portable design. Its lightweight nature makes it easy to handle, reducing operator fatigue during extended use.

How fast does the 40KW Handheld Induction Welding Machine work?

Induction heating provides quick and efficient heating, resulting in faster welding times compared to traditional methods, improving overall productivity and reducing downtime.

Does the machine require any special maintenance?

Regular maintenance includes checking the induction coils, ensuring proper cooling, and calibrating the controls. The machine has fewer moving parts compared to traditional welding equipment, reducing the overall need for maintenance.

What safety precautions should be followed while using the machine?

Always follow the manufacturer’s safety guidelines, wear appropriate protective gear such as gloves and eye protection, and ensure the work area is clear of flammable materials. The machine features various protective mechanisms to ensure safe operation.

RELATE PRODUCTS

REQUEST A QUOTE

Do you need help with choosing our products?

Fill out this form to get in touch with us.

Whatsapp

Whatsapp