200-260KW Intermediate Frequency Induction Forging System

Model : KXZP-200/KXZP-260

Rated Power: 200KW/260KW

Output Oscillation Frequency: 1-8KHz

Input Current: 320A/415A

PRODUCT DETAILS

Intermediate frequency induction forging furnace is induction heating equipment for the purpose of heating metal forging or tempering heat treatment.

| Intermediate Frequency Induction Forging Machine | ||

| Model | KXZP-200 | KXZP-260 |

| Power | 200KW | 260KW |

| Input Voltage | Three phase 380V/50Hz | Three phase 380V/50Hz |

| Input Current | 320A | 415A |

| Output Oscillation Frequency | 1-8KHz | 1-8KHz |

| Cooling Water Pressure | 0.15-0.3MP | 0.15-0.3MP |

| Dimension (L*W*H) | 2000*1200*1200mm | 2400*1200*1200mm |

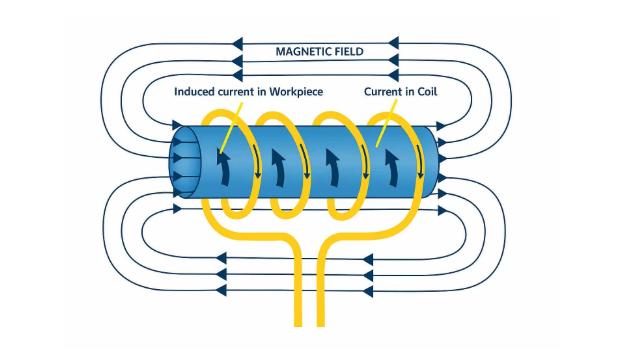

Intermediate frequency induction forging system offers a controllable and localized method of heat without contact with the parts (components) being heated. The heat of the electromagnetic heating equipment is generated by inducing an alternating magnetic field into electrically conductive materials. Electromagnetic heating equipment is very low cost to run and normally creates significant cost savings versus other traditional process heating technologies.

Intermediate frequency heating furnace is induction heating equipment for the purpose of heating metal forging or tempering heat treatment.

It is generally used for heating before forging and the heating temperature is 1200 degrees, while the heating temperature for tempering heating is generally within 1000 degrees. This intermediate frequency heating application determines that the heating principle of an intermediate frequency heating furnace is only for heating purposes and cannot melt metal.

Intermediate frequency furnace is mainly composed of variable frequency device and induction coil, power frequency 50 Hz alternating current frequency conversion device would turn into intermediate frequency 100 Hz – 10000 Hz of alternating current, the three-phase alternating current into direct current (dc) after rectifying power frequency, and then laid adjustable intermediate frequency electric current, direct current supply by the capacitor and inductor in the flow of intermediate frequency alternating current, generate high-density magnetic field lines in the induction coil, induction coil, and cutting in cheng fang of metal materials, produce a lot of eddy current in the metal materials.

The frequency conversion device and induction coil of the intermediate frequency heating furnace make the heated metal material produce eddy current, which also has some properties of the intermediate frequency current, that is, the free electrons of the metal itself flow in the metal body with resistance to produce heat., for example, put a metal cylinder has alternating medium frequency current in the induction coil, the metal cylinder has no direct contact with an induction coil, electric coil temperature is very low, but the surfaces are heated to redness, and even melt, and the redness and melting speed as long as adjust the size and the strength of the current frequency can be achieved.

If the cylinder is placed in the center of the coil, the temperature around the cylinder is the same, and the heating and melting of the cylinder do not produce harmful gases or light pollution to the environment.

The frequency range is wide, from 1 kHz to 20 kHz, and the appropriate frequency can be selected according to the specific diameter of the heated workpiece.

The induction coil is 500mm-1m long when the whole material is heated by medium frequency forging furnace, and multiple materials are heated at the same time, which further ensures the heat penetration effect.

The intermediate frequency forging furnace adopts continuous heating mode, and the load inside the induction coil is relatively balanced, which overcomes the huge change of the actual heating power of the equipment caused by the huge change of the load when the load of a singlebar rises from room temperature to 1100°C in the whole heating process, so that the actual power of the equipment can be guaranteed to be above 85% of the rated power value in the whole continuous heating process, and the equipment can be effectively utilized.

When heating nonferrous metals such as copper and aluminum, the actual power of the equipment can also reach more than 85% of the maximum power by reasonably designing the induction coil and capacitor, and the heating capacity can reach 3.5 kg/kW hour when heating copper.

Application of Frequency Induction Forging System

Induction forging has become indispensable across various industries due to its precision and efficiency:

1. Automotive Industry:

- Engine Components: Crankshafts, connecting rods, camshafts

- Transmission Parts: Gears, shafts, synchronizer hubs

- Suspension Components: Control arms, knuckles, axle components

- Steering System Parts: Tie rods, pitman arms

2. Aerospace Sector:

- Turbine Components: Blades, discs, shafts

- Landing Gear Parts: Struts, torque links, actuator components

- Structural Components: Brackets, fittings, junction elements

- Fastening Systems: High-strength bolts and fasteners

3. Industrial Equipment:

- Heavy Machinery Parts: Gears, shafts, couplings

- Mining Equipment: Drill bits, bucket teeth, wear parts

- Construction Machinery: Hydraulic component forgings, structural elements

- Material Handling Equipment: Hooks, chains, lifting components

4. Energy Sector:

- Power Generation: Turbine components, generator parts

- Oil & Gas: Valves, flanges, fittings, drilling components

- Nuclear Industry: Specialized high-integrity components

- Renewable Energy: Wind turbine components, hydropower elements

5. Railway Industry:

- Wheel Components: Axles, wheel centers

- Suspension Systems: Springs, damping elements

- Coupling Mechanisms: Drawbars, couplers

- Track Components: Rail fastening systems, switch components

6. Medical Equipment:

- Surgical Instruments: Forceps, clamps, retractors

- Implant Components: Joint replacement parts, fixation devices

- Medical Device Components: Precision mechanical elements

These applications demonstrate the versatility of induction forging in producing components that require exceptional mechanical properties, dimensional accuracy, and reliability.

REQUEST A QUOTE

Do you need help with choosing our products?

Fill out this form to get in touch with us.

KEXIN Induction Forging System

1200-1500KW INTERMEDIATE FREQUENCY INDUCTION FORGING SYSTEM

Key Advantages of Induction Forging

Energy Efficiency: Saves 30-50% energy compared to gas/coal furnaces.

Material Savings: Low oxidation (0.5% loss vs. 2-3% for coal) means less scrap and 95% steel utilisation.

Uniform Heating: Small core-to-surface temperature difference, improving die life and forging quality.

Fast & Clean: Rapid heating and minimal pollution/noise, with no need for extensive pre-firing.

Versatile: Suitable for steel, cast iron, nonferrous metals, and various batch sizes.

RELATED QUESTIONS

What’s “Intermediate Frequency”?

Intermediate frequency is a range (1-100 kHz) that balances rapid heating with sufficient depth for forging larger items, unlike very high frequencies for surface hardening.

What’s the common frequency for induction heating machines?

- High frequency: 30kHz-100kHz.

- Medium frequency: 1kHz-10kHz.

- Ultra high frequency: 200kHz-800kHz.

- Super audio frequency: 20kHz-50kHz.

What is induction forging?

Induction forging is an advanced metal forming process that uses electromagnetic induction to heat metal workpieces to their forging temperature before shaping them with dies. Unlike conventional forging methods that rely on external heat sources such as furnaces or open flames, induction forging generates heat directly within the workpiece itself.

How does frequency affect induction heating?

The low-frequency current causes induction and heat deep into the material. But high-frequency electric current produces shallow induction and heat from the material surface.

What is the difference between high-frequency and low frequency induction heaters?

Higher frequencies are used for applications like brazing, soldering, annealing or heat treating, where surface heating is desired. Lower frequencies are preferred for applications requiring through-heating of the parts to the core like forging and die heating.

How does an intermediate frequency induction forging system work?

- Power Conversion: Standard 50/60 Hz AC power is converted into a higher intermediate frequency (typically 300 Hz – 20 kHz).

- Magnetic Field Generation: This intermediate frequency current flows through an induction coil, creating a dense, alternating magnetic field.

- Eddy Currents: When the metal workpiece is placed in the coil, the magnetic field induces strong eddy currents within the metal.

- Resistive Heating: The resistance of the metal to these currents generates heat directly in the workpiece, causing it to reach forging temperature quickly and uniformly.

RELATE PRODUCTS

REQUEST A QUOTE

Do you need help with choosing our products?

Fill out this form to get in touch with us.

Whatsapp

Whatsapp