Boosting Forge Line Efficiency with Induction Bar Heaters

Rapid advances in industrial technology continue to challenge traditional methods, opening the door to more efficient and effective solutions.

Among these modern innovations stands out the induction rod heater. Induction heaters bring a range of significant advantages to the forging process.

In this article, we will explore the advantages of using induction rod heaters in forging applications.

Due to their efficient heating capabilities and environmentally friendly characteristics, induction rod heaters have become the first choice for modern forging processes.

What is Induction Forging?

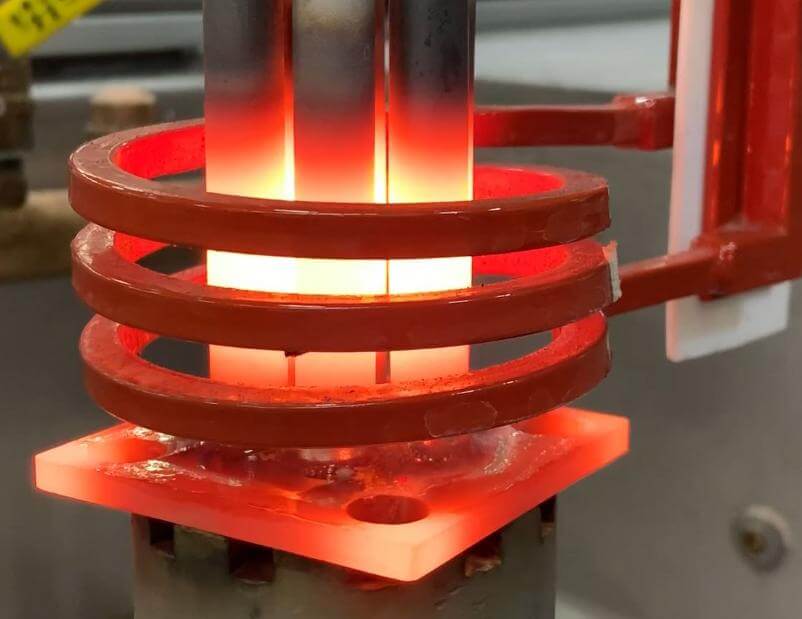

Induction forging refers to the use of an induction heater to pre-heat metals prior to deformation using a press or hammer. Typically metals are heated to between 1,100 and 1,200 °C (2,010 and 2,190 °F) to increase their malleability and aid flow in the forging die.

Forging is one of the oldest processes goldsmiths use to shape metal and form metallic objects of desired shape and size. The process imparts multiple mechanical properties such as strength, fatigue resistance, and impact resistance to the forged material.

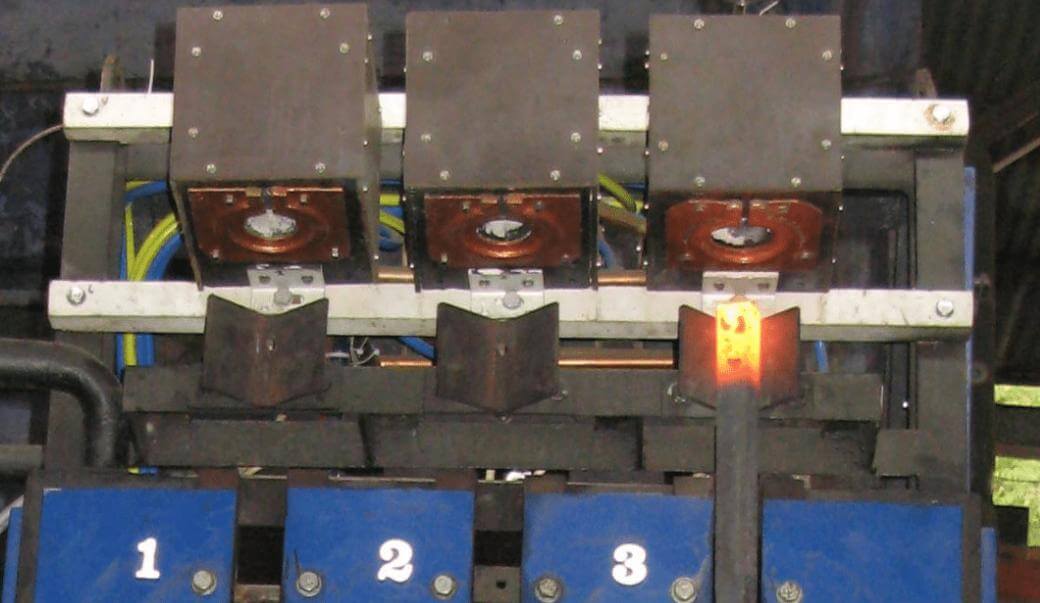

Working Principle of Induction Bar Heater

Induction heating is a non-contact process which uses the principle of electromagnetic induction to produce heat in a workpiece. By placing a conductive material into a strong alternating magnetic field, electric current is made to flow in the material, thereby causing Joule heating.

In magnetic materials, further heat is generated below the Curie point due to hysteresis losses. The generated current is predominantly in the surface layer, the depth of this layer being dictated by the frequency of the alternating field and the permeability of the material.

Components of Induction Bar And Heating Systems

Induction rod heaters have revolutionised the forging industry, enabling unparalleled efficiency and precision in the heating process.

These advanced systems consist of key components that work together to provide precise and efficient heating for a variety of forging applications.

Below, we will explore the key features and functions of forging induction heating machines, as well as the key components of the heating system. In addition, we will focus on their role in the induction rod heating process.

Induction Heating Machine

- Heart of the system, generating high-frequency electric currents

- Allows precise power and frequency control for various workpiece requirements

- Equipped with advanced temperature monitoring and safety features

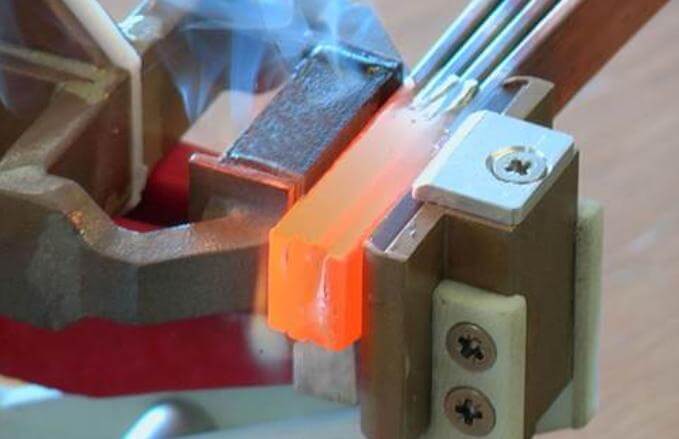

Inductor Coil

- Surrounds the workpiece and generates the magnetic field for heating

- Tailored design for uniform heating across the bar end

Cooling System

Essential for maintaining the inductor coil temperature and preventing overheating

Control Panel

- Contains a user interface and controls for the induction heating machine

- Enables operators to set heating parameters, monitor temperature, and adjust settings

Power Supply

- Critical component providing high-frequency electric current

- Converts electrical energy into the desired frequency and voltage for optimal heating efficiency

Temperature Sensors

- Integrated into the system for accurate monitoring of workpiece temperature

- Provides real-time feedback for precise temperature control

Feeding and Drive System

Transfer bars/ workpieces into the induction coil for heating

The Benefits of an Induction Bar Heater for Forging

1. Rapid and Precise Heating

Induction bar heaters provide rapid and precise heating, which enables manufacturers to achieve specific temperature profiles quickly and consistently.

The induction heating process relies on electromagnetic induction, where an alternating current generates a magnetic field around the workpiece, causing it to heat up. This method ensures that the required temperature is attained precisely, minimizing material wastage and improving energy efficiency.

2. Enhanced Efficiency and Productivity

Induction bar heaters significantly enhance efficiency and productivity in forging operations. Induction heating for forging provides faster heating cycles when compared to traditional methods. It takes less time to reach the required temperature, making it quicker production and higher throughput.

The benefit of an induction heater directly translates to increased productivity and profitability. Besides, due to the controlled and uniform heating process, it largely reduces the need for additional post-heating treatments, further streamlining the production process.

3. Energy and Cost Savings

Compared to traditional heating methods, induction bar heaters have the advantage of remarkable energy efficiency. As the principle of induction heating, it can directly heat the workpiece without heating the surrounding air, which leads to minimal heat loss.

This efficiency not only reduces energy consumption but also brings substantial cost savings for manufacturers, making induction heaters a cost-effective choice in the long run.

4. Precision and Uniformity in Heating

Precision heating is another crucial advantage offered by the Induction Bar Heater. Due to the precise control of the magnetic field and current, the induction heater enables uniform heating, ensuring a consistent quality of forged components.

This uniformity of induction heating reduces wastage due to defects, providing a superior output.

5. Environmentally Friendly and Clean

It’s an eco-conscious option for choosing the induction bar heaters for forging processes. It contributes to a cleaner and greener environment as induction bar heaters do not involve the burning of fossil fuels or the production of harmful emissions.

The absence of open flames or hot surfaces also enhances the safety of the workplace, reducing the risk of accidents.

6. Compact Design and Space Efficiency

Induction bar heaters boast a compact and space-efficient design compared to bulky and space-consuming conventional furnaces.

This feature of induction bar heaters is particularly advantageous for facilities with limited floor space. Besides, their modular build allows for easy integration into existing forging lines, making them a versatile choice for various manufacturing setups.

Conclusion

Kexin provides customised induction heating solutions to meet the unique needs of enterprises. Our team of experts works closely with customers to understand their specific forging needs and provides responsive support throughout the pre-sales and after-sales process.

Kexin focuses on providing quality products and innovative solutions to ensure that every customer can get the maximum return on investment.

KEXIN’s induction melting furnace has higher thermal efficiency and lower energy consumption. They can produce a mild metal bath mixture, mixing a uniform alloy at a constant and uniform temperature. For these reasons, this type of furnace is the first choice for induction melting. Kexin products can flexibly meet all customer requirements.

Can we help you?

Whatsapp

Whatsapp