Understanding the Essential Components of an Induction Heating System

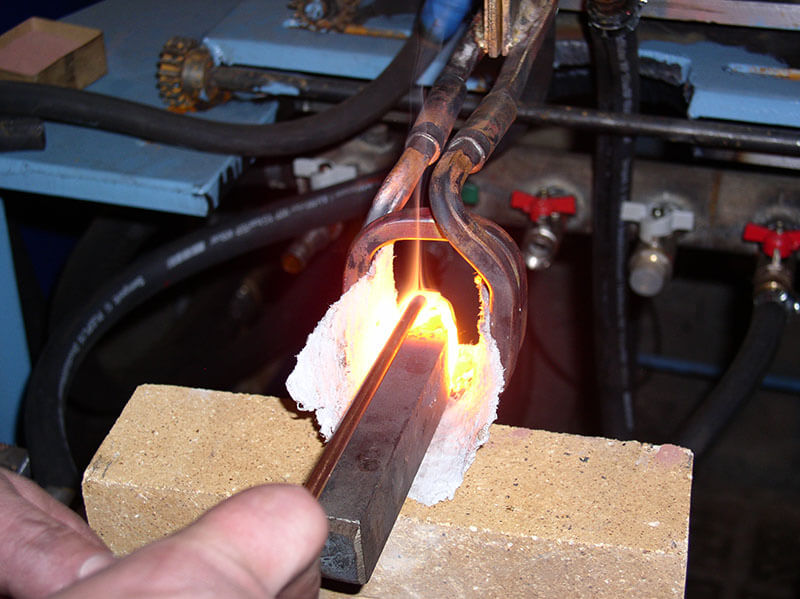

Induction heating is a highly efficient way to heat electrically conductive materials, such as metals and semiconductors. The process works by using electromagnetic induction to transfer heat through an inductor, creating an electromagnetic field within a coil.

This can quickly and effectively heat up and even melt materials like steel, copper, brass, graphite, gold, silver, aluminium, or carbide.

One of the key advantages of induction heating is that the heat is generated directly within the object being heated, rather than relying on external sources of heat conduction.

This enables rapid heating without the need for external contact, which is especially beneficial in situations where contamination could be a concern.

Industries rely on induction heating for various applications including metallurgy’s heat treatment processes, semiconductor manufacturing’s Czochralski crystal growth and zone refining techniques, and melting refractory metals that require extremely high temperatures.

Induction cooktops also utilize this technology for efficient cooking purposes.

What makes up an induction heating system?

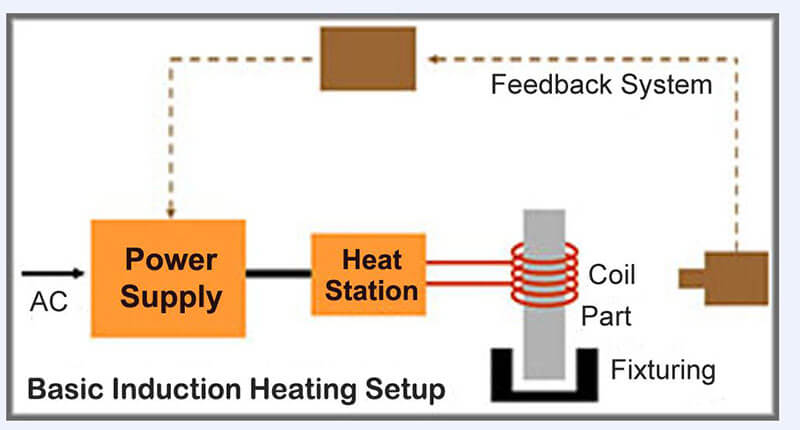

An induction heating system comprises three main elements: a power supply, an induction coil, and a workpiece. The power supply delivers alternating current to the coil, producing a magnetic field.

Once the workpiece is positioned within the coil, this magnetic field induces an eddy current within it. Consequently, this process generates accurate amounts of precise heat in a localized manner without any direct contact between the coil and the workpiece.

Power Supply

The power supply is an essential component of an induction heating system, as it determines the performance and efficiency of the system. Induction power supplies come in various types, but solid-state inverters are known for their superior efficiency.

A typical solid-state inverter power supply consists of two main sections: the rectifier and the inverter. The rectifier section uses diodes or thyristors to convert line AC currents into DC.

The DC current then flows into the inverter section, where solid-state switches (such as IGBTs or MOSFETs) convert it back into an alternating current at a high frequency (typically between 10KHz-600KHz).

IGBTs are capable of handling higher power levels and lower frequencies, while MOSFETs excel at lower power levels and higher frequencies. Each has its own advantages depending on the specific needs of the application.

Induction coil

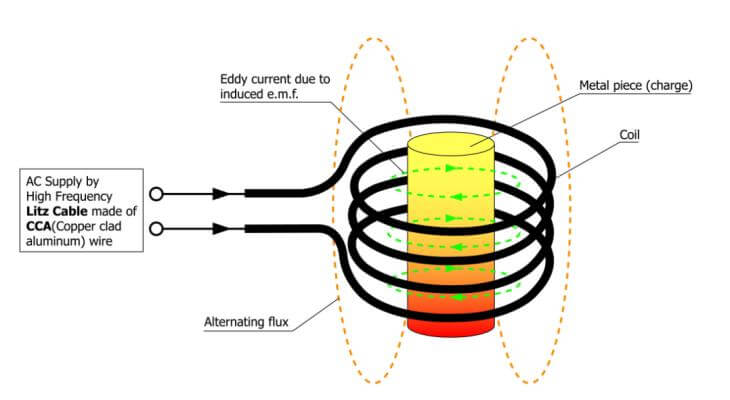

The induction coil is responsible for generating the necessary magnetic field for induction heating. This is achieved by passing alternating current (AC) through the coil. The size and shape of the coil can be customized to suit specific applications.

Every workpiece is unique and requires a specific approach to achieve optimal heating. Induction coils are designed in different shapes and sizes to suit various workpiece geometries.

For smaller workpieces, a smaller coil is typically used to ensure precise and focused heating. Conversely, larger workpieces require larger coils to achieve uniform heating across a wider surface area.

The coil acts as a pathway for the electromagnetic energy to flow through, creating a magnetic field that induces heat in the workpiece.

So, choosing the right coil is essential in achieving successful induction heating, as it ensures efficient heat transfer and minimizes any heat loss. By selecting the appropriate induction coil based on the size and shape of the workpiece, manufacturers can ensure consistent and effective heating for their applications.

Cooling System

We recommend customers prepare a water tank and a water pump to work as the cooling system. If customers have a sufficient budget, then an industrial cooling chiller will be more available.

Key Benefits of Induction

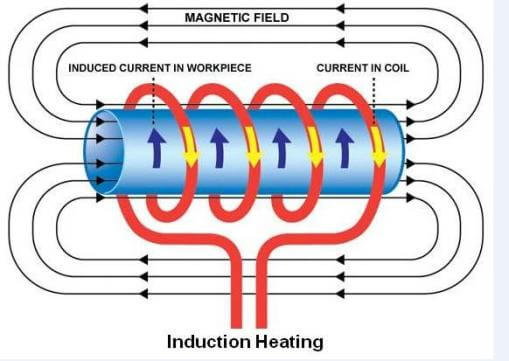

Induction heating is a process that utilizes the principle of electromagnetic induction to heat an electrically conductive material. It involves the generation of alternating magnetic fields, which in turn induces electrical currents within the material.

These currents, known as eddy currents, flow through the material and produce heat due to resistance. Induction heating offers several advantages including fast and precise heating, improved energy efficiency, and enhanced control over the heating process.

Fast Cycle Times

With induction heating technology, heat is produced instantly and directly within the part being heated. Thus heat can be supplied as quickly as a material will permit it, eliminating typical soak times associated with radiation or convection heat technologies.

Accurate Heat Zones

Through the development of an induction coil combined with the specification of the proper power and frequency, they can isolate or pinpoint a heat zone, small or large without affecting surrounding areas.

The result is minimal distortion in part being heated, yielding higher quality production. Additional infrared temperature control devices can also be added for further control of a process.

Consistent and Repeatable

Due to the development coil ent of Solid-State power supplies, the heating pattern produced by a given induction coil will be consistent from day to day, month to month.

Since the induction coil is not in any contact with the part being heated and the part is being presented to the in a consistent fashion, the process will remain repeatable, unlike traditional flame heating or resistance heating, which have constantly changing characteristics.

Space Requirements and Efficiency

Due to the smaller space requirements for induction heating over many traditional heating methods, this technology lends itself to bench-top/work cell environments and in-line semi or fully-automated processes.

In addition, Induction Heating technology is energy efficient, power consumption to create the output power is minimal and in idle or stand-by conditions power consumption is greatly reduced since the power is only on when the system is being utilized for the intended process.

Environmentally Friendly

Induction heating is an extremely clean heat. It does not produce harmful emissions or loud noise. It does not heat the environment or area outside the work coil, since the heat is only generated in the workpiece being heated. Thus induction heating assists in creating more favorable working conditions.

Working on an Induction Coil

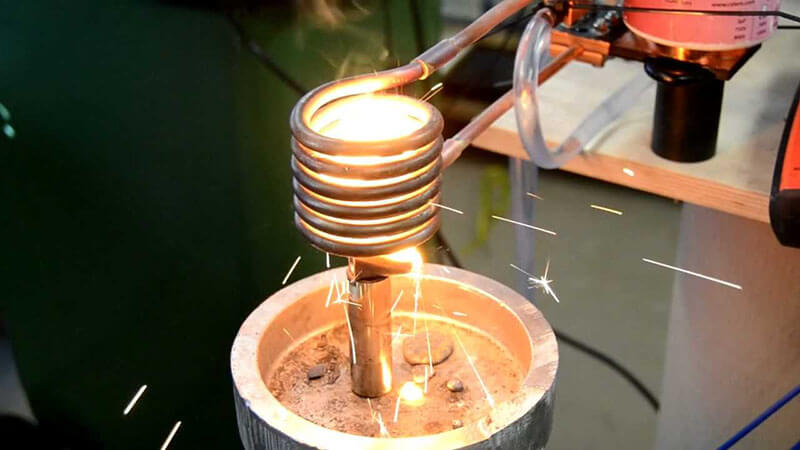

An induction heater consists of an electromagnet and an electronic oscillator that passes a high-frequency alternating current (AC) through the electromagnet. The rapidly alternating magnetic field penetrates the object, generating electric currents inside the conductor called eddy currents.

The eddy currents flowing through the resistance of the material heat it by Joule heating. In ferromagnetic (and ferromagnetic) materials like iron, heat may also be generated by magnetic hysteresis losses.

Features of Induction Heating

Choosing induction heating offers numerous advantages both in terms of efficiency and cost-effectiveness.

Induction heating is an environmentally friendly process as it produces no fumes or CO2 emissions. Electricity generating companies can easily monitor and control the emissions at one site.

Due to induction heating’s ability to heat only a small proportion of the material, typically less than 5% of the total mass, it consumes less energy compared to conventional furnace heat treatment methods. This efficiency translates into cost savings when heat-treating components.

Another benefit is that induction heating minimizes heat treatment distortion, making the majority of heat-treated components ready for assembly without additional processing. This reduction in distortion leads to improved precision and surface finish.

Furthermore, specifying induction hardening can help save money by lowering grinding costs which typically account for 25-30% of a component’s total cost. Modern CNC lathes can accurately turn components to size with a superior surface finish compared to grinding.

Induction heating allows for selective hardening, making it ideal for components that require specific areas to remain soft after heat treatment. This process eliminates the need for costly “stopping off” techniques used in traditional furnaces.

Important Considerations when Selecting an Induction Heating System

One crucial factor to consider when choosing an induction heating system is the heating power. The heating power directly impacts the speed and effectiveness of the heating process.

It is essential to determine the appropriate heating power based on factors such as material, shape, size, and other characteristics of the object being heated.

Another consideration is the heating frequency. The frequency at which the induction heating equipment operates plays a significant role in achieving optimal results.

Different frequencies are suitable for various materials and heating methods. It is important to select a frequency that aligns with your specific requirements.

The stability and reliability of the equipment are also vital aspects to keep in mind. To ensure seamless operation and performance, it is recommended to choose manufacturers and brands that have a proven track record in delivering reliable induction heating equipment. Experience, mature technology, and a commitment to quality should be key criteria when making your selection.

Additionally, price and after-sales service should be taken into account during the decision-making process. The cost of induction heating equipment can vary based on factors such as quality, power capacity, and frequency capabilities.

It’s important to choose equipment that reasonably aligns with your needs while considering whether comprehensive after-sales support is provided by the manufacturer or supplier.

By carefully considering these factors, you can make an informed decision when selecting an induction heating system that best suits your specific requirements.

KEXIN provides high-frequency induction heating machines, medium-frequency induction heating equipment, induction melting furnaces, induction brazing machines, induction forging equipment etc.

KEXIN’s induction melting furnace has higher thermal efficiency and lower energy consumption. They can produce a mild metal bath mixture, mixing a uniform alloy at a constant and uniform temperature. For these reasons, this type of furnace is the first choice for induction melting. Kexin products can flexibly meet all customer requirements.

Can we help you?

Whatsapp

Whatsapp