How to Fix the Common Problems with Induction Heaters?

Nowadays, with the high heating efficiency of induction heater, more and more industrialists are starting to use induction heater as their first choice to optimize their heating processes.

As a prospective buyer, you might be wondering why induction heating is such a game-changer for industrial heating processes. Let us introduce more details about induction heaters for you.

Induction heating machines are widely applied in various industries. However, just as any other equipment, it is no doubt that an induction heater will come up with some issues after long-term of operation.

The following article is mainly for explaining some typical and common problems or issues about induction heaters, and also the relative methods to solve them.

Power Problems

Generally speaking, after the installation of induction heater, the power problem is one of the main induction heater technical issues that can result in your induction heater not working or performing inconsistently.

For example, induction heater is failing to start, intermittent power loss during operation, or some fluctuations.

Please double check if there is any damage or wear of your power supply connections and cables and also measure if the supplied voltage and current is match to the induction heater or not.

Power Problems Solution: Regarding the power problems of induction heating machine, please recheck if the power supply is delivering consistent power without any overheating.

A surge protector can help safeguard the power supply from external surges, so if possible, please prepare one for the induction heating equipment. Besides, replace all the damaged cables and check all electrical connections again to maintain consistent power delivery.

Electrical Noise Interference

External electrical noise interference can lead to operational issues in induction heaters, including unstable heating performance and unexpected shutdowns. Moreover, such interference can also affect nearby electronic devices.

Solution for Electrical Noise Interference: Proper grounding of the induction heater is essential to significantly reduce electrical noise. Additionally, using shielded cables for power and control connections can help minimize electromagnetic interference.

To further reduce potential disturbances, ensure that any equipment likely to cause interference is moved away from the induction heater.

Overheating Problems

Overheating, which can cause serious induction heater safety issues, is somehow frequently happened during the operation of induction heating equipment.

Consider it as overheating if the induction heater becomes very hot to the touch or shuts down unexpectedly. Please check and Look if there is any burn marks or discoloration on the workpiece or coil, which are telltale signs.

Overheating Problems Solution: Frequently check if the cooling system is functioning correctly; Make sure that the water flow is adequate through the induction heater coil in avoid of overheating; What’s more, check if the input power is suitable as recommended range for induction heater. Above are the best and valid solutions for induction heater problems.

Inconsistent Heating Problems

It could be very annoying that if the inconsistent heating of induction heater is happened. For example, some parts of the workpiece heating is unevenly, which will lead to uneven hardness or melting as expected.

The main reason could be the misaligned coil or improper positioning of the workpiece. To identify this, visually inspect your workpiece for temperature irregularities and measure the temperature at different points.

Inconsistent Heating Solution: To maximum the efficiency of induction heater, make sure that the workpiece is correctly centered within the induction heating coil.

Ensure that the induction heating coil is properly centered within the workpiece. Besides, double check if the power supply is delivering consistent power without fluctuations.

Coil Damage Problems

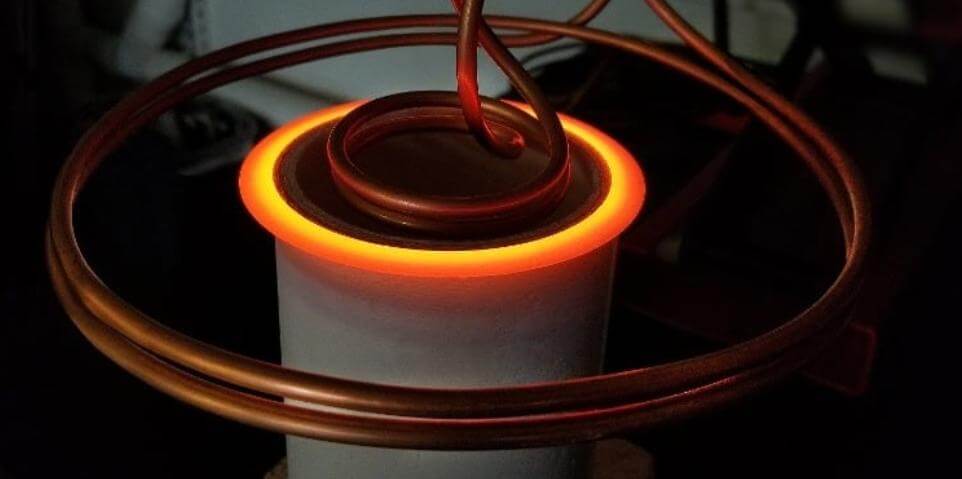

The damage of induction heating coil can seriously affect the performance and function of induction heater. Please take a notice if there is any visible crack or break of the induction heating coil, if so, it could somehow decrease the induction heating performance, or could be some unusual noises during operation.

Frequently check if there is any damage sign of the induction heating coil or any unusual noises or vibrations is heard.

Coil Damage Solution: In order to solve these induction heating coil problems, it’s very important to replace the damaged coils timely so that to maintain the induction heating efficiency and to prevent further heating problems.

It can largely minimize the risk of induction heating coil damage if the coil is properly handled and installed.

How to maintain the induction heater?

To avoid common induction heater issues, it’s essential that to do some preventive maintenance for running induction heater optimally and functionally. Following are some simple steps to help you maintain your induction heating equipment effectively.

Regular Inspections and Maintenance

First of all, it’s crucial to check and maintain the induction heater frequently and regularly. For example, checking the power supply of the induction heater, cleaning the induction heating coils, and also ensuring the water cooling system is working properly.

- To Check the Power Supply of Induction Heater:

Make sure that the power supply of the induction heating equipment is consistent and there are no overheating problems. Inconsistent power can cause some performance issues.

- To Clean the Induction Heating Coils:

Dust and debris can accumulate on the coils, which will affect the heating efficiency. A clean induction heating coil can heat more evenly and perform better.

- CoolingWater System:

Overheating can damage the induction heater and also shorten its lifespan, so a well-functioning cooling system can avoid overheating problems.

Routine Induction Heater Maintenance

It will be a good habit to make some routine maintenance for induction heating machines, which can prevent various induction heater problems before they become serious.

- Daily Maintenance: Quick visual inspections and minor cleanups.

- Weekly Maintenance: More detailed inspections and cleanings.

- Monthly Maintenance: Comprehensive checks and preventive maintenance tasks.

Conclusion

When it comes time to maintain your induction heater, the goal isn’t just to address existing issues but also to prevent them from occurring in the first place.

KEXIN offers reliable and comprehensive maintenance services, with trained technicians ready to handle a wide range of induction heater problems. This ensures your equipment operates efficiently and lasts longer.

KEXIN’s induction melting furnace has higher thermal efficiency and lower energy consumption. They can produce a mild metal bath mixture, mixing a uniform alloy at a constant and uniform temperature. For these reasons, this type of furnace is the first choice for induction melting. Kexin products can flexibly meet all customer requirements.

Can we help you?

Whatsapp

Whatsapp