The Benefits of Induction Heating Equipment in Manufacturing

Induction heating is when an electrically conductive object is heated by electromagnetic induction. The process can be used to heat metals, glass, and other conductive materials.

Induction heating has a number of advantages over other methods of heating, including improved efficiency and greater control. This blog post will explore the benefits of induction heating equipment in manufacturing.

What is induction heating?

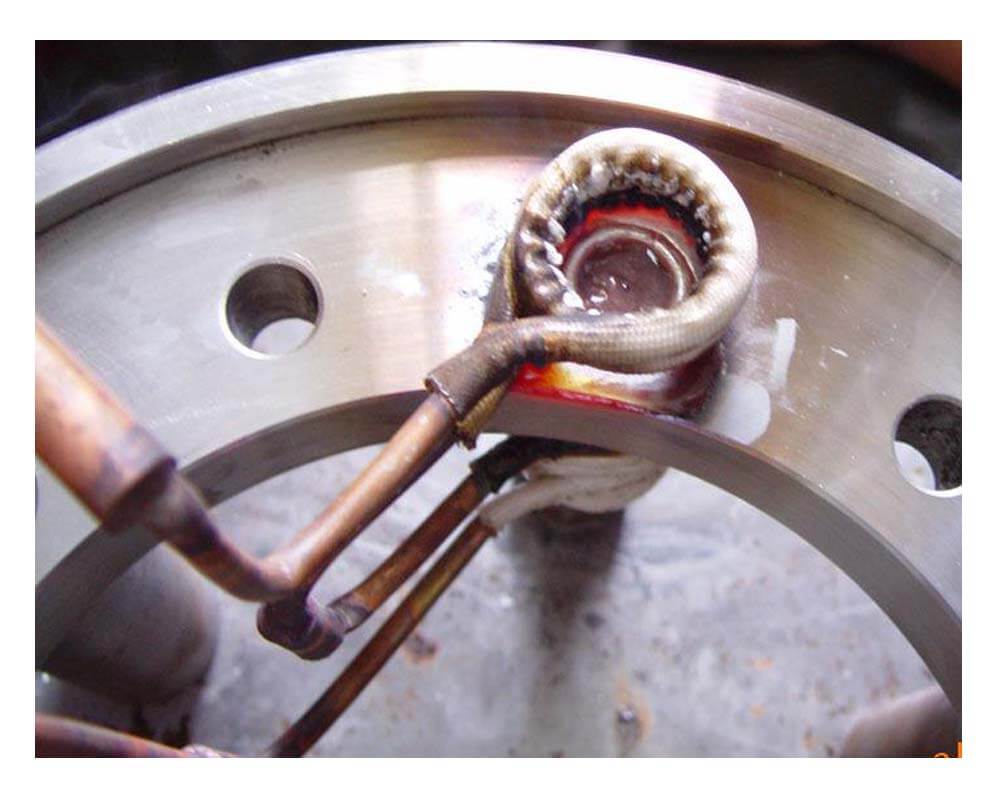

Induction heating is the process of heating a conductive object by electromagnetic induction. In this process, alternating current passes through a coil (induction coil) that is wound around the object to be heated.

When an electric current passes through a coil, it creates a magnetic field. If a piece of metal is placed inside a coil, a magnetic field will cause an electric current to flow through the metal. The resistance of the metal to the current generates heat, which heats the metal by induction.

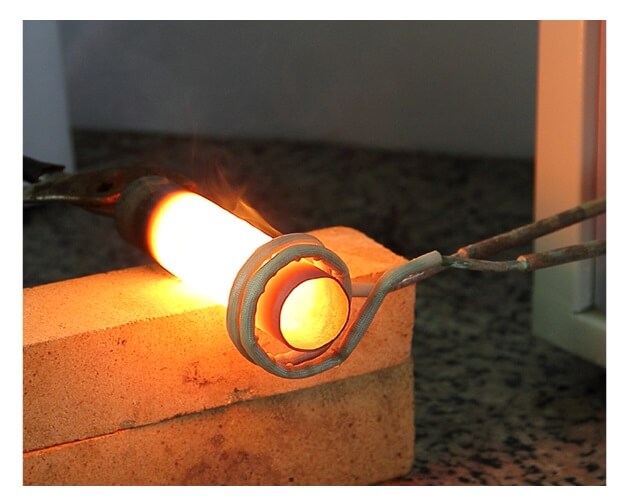

Induction heating is usually used in industrial applications to heat metals for forging, melting, or sintering. Induction heating is also used in home applications such as cooking, drying, and space heating.

How does induction heating work?

Induction heating is a heating method that uses electromagnetic induction to heat objects. The object to be heated is placed in a magnetic field and passed through an alternating current. The current creates a magnetic field that interacts with the object, causing it to heat up.

Induction heating is used in industries ranging from aerospace to automotive. It is also used in a variety of applications, such as heat treatment, welding, brazing, and soft brazing.

What are the benefits of induction heating for manufacturers?

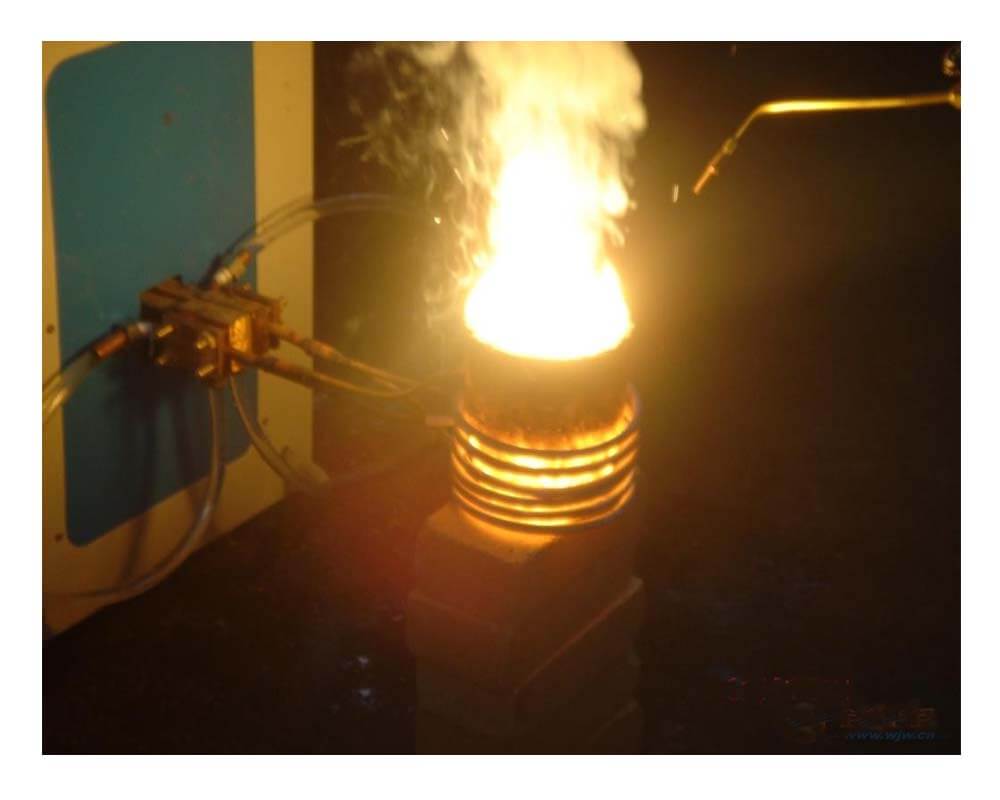

Induction heating has been widely used in various industries since the 1950s. Induction heating is the process of using an electric current to generate heat inside an object. This heating method is efficient and accurate, making it ideal for manufacturing.

Induction heating has many benefits for manufacturers, including increased efficiency, improved accuracy, and reduced costs. In addition, induction heating can be used in a variety of applications, such as heat treatment, hardening, welding, and brazing.

If you are a manufacturer, induction heating can offer many advantages to your business. This is a safe, efficient, and accurate way to heat objects, saving you time and money.

Why is induction heating becoming increasingly popular?

Induction heating is a heating method that uses electromagnetic induction to heat objects. Because of its high efficiency, accurate control, safety, and many other advantages, more and more popular.

Induction heating has many advantages over other heating methods such as resistance heating and flame heating. It is much more efficient, which means less energy is lost as heat. This makes it more environmentally friendly and helps reduce energy costs.

In addition, induction heating is more accurate, allowing for better control of the heating process. This is particularly beneficial for precision materials that can be damaged by overheating.

Finally, induction heating is safer than other methods because there is no open fire and no risk of electric shock. Induction heating is an effective, efficient, and safe heating method, which is becoming more and more popular.

How can induction heating be used in manufacturing?

Induction heating is a heating method that uses an electromagnetic field to generate heat in the object. The technology is commonly used in manufacturing because it can be used to heat the metal without direct contact.

This is useful for applications such as hardening or welding, as it allows for a more controlled and consistent heating process.

Several different types of induction heating are commonly used in manufacturing. These include surface induction heating, conduction induction heating, and electromagnetic induction heating.

Each of these methods has its advantages and disadvantages, so it is important to choose the right type of induction heating for your particular application.

What are the applications of induction heating equipment?

Induction heating equipment has a wide range of applications. It can be used for everything from heating metals to cookware. Induction heating equipment uses an electromagnetic field to generate heat. This type of equipment is often used in commercial and industrial settings.

Some of the most common applications for induction heating equipment include:

Heating metals

Induction heating equipment can be used to heat metals for forging, welding, and other applications.

Cooking

Induction cookers use induction heating to cook food. This type of cooking is fast and efficient.

Industrial applications

Induction heating equipment is often used in industrial settings for things like heat treating metals.

If you are looking for a way to heat metals or cook food, induction heating equipment may be the right solution for you.

Induction heating equipment has a number of benefits in manufacturing. It is fast and efficient, can be used for a variety of applications, and is gentle on delicate materials.

Additionally, induction heating equipment is becoming increasingly portable and affordable, making it a viable option for more factories and businesses.

To learn more about how induction heating equipment can benefit your business, please contact Kexin Electronic. Our email address is nancy-sales@foxmail.com.

KEXIN’s induction melting furnace has higher thermal efficiency and lower energy consumption. They can produce a mild metal bath mixture, mixing a uniform alloy at a constant and uniform temperature. For these reasons, this type of furnace is the first choice for induction melting. Kexin products can flexibly meet all customer requirements.

Can we help you?

Whatsapp

Whatsapp