The Strong Points and Advantages of Induction Heating

In modern manufacturing and industrial processes, efficiency, precision and sustainability are of paramount importance. Induction heating is a shining example of technological innovation that embodies these qualities.

This cutting-edge heating method has gained huge traction in various industries due to its numerous benefits and advantages.

From improved energy efficiency to precise control and reduced environmental impact, induction heating offers numerous benefits, making it a first choice for many applications.

Generally speaking, compared with direct heating by traditional resistance furnaces and flame furnaces, induction heating has obvious advantages such as energy saving, environmental protection, and safety. This is specifically reflected in the following aspects.

High efficiency

One of the outstanding advantages of induction heating is its excellent energy efficiency. Unlike traditional heating methods, such as gas or flame heating, induction heating targets specific areas that require heat.

By using electromagnetic induction to generate heat directly within the material, induction heating minimizes energy waste and significantly shortens heating times.

The induction heating efficiency is 30% ~ 50% higher than the flame furnace and 20% ~ 30% higher than the resistance furnace, which has an obvious energy-saving effect.

This efficiency not only saves costs but also helps achieve the Sustainable Development Goals by reducing overall energy consumption and carbon footprint.

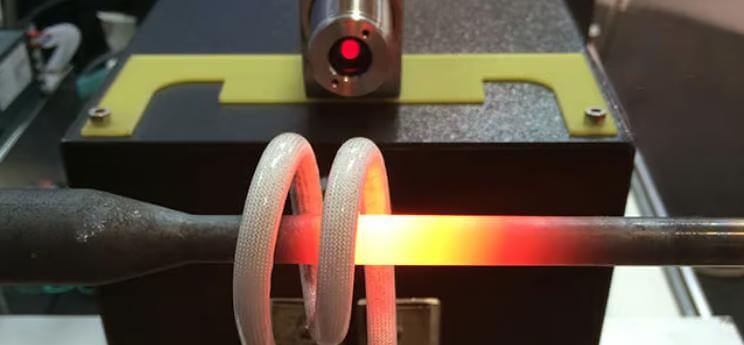

High heating temperature and short time

The heating temperature of induction heating is high and the time is short, which means the heating speed is fast.

It shows that induction heating has higher working efficiency and higher output per unit of time than resistance furnaces and flame furnaces.

The heating speed of the induction heating machine is fast, and the surface oxide scale burning rate of the heated metal workpiece is low, saving materials and costs, which is especially important for heating precious metals.

For example, under normal circumstances, when metal parts are heated by thermoforming, the metal burning loss rate of induction heating is about 0.5%, while the metal burning loss rate of flame furnace heating is about 1% to 3%. In other words, induction heating saves about 2% of the material compared with flame heating.

Easy to realize automatic control

Induction heating can perform timely and accurate automatic control based on the current status of the heated workpiece, such as adjusting the power or frequency through analog or digital circuit processing, and automatically adjusting the heating temperature or depth of the workpiece to meet process requirements. The adjustment of induction heating is relatively fine.

The heating power of induction heating machines is usually adjusted by adjusting parameters such as phase shift and pulse duty cycle.

Once the heating temperature of the induction heating machine is determined according to the process requirements, it is maintained at a constant temperature due to the negative feedback of the white body, thereby achieving constant power and constant temperature control.

The induction heating machine has good temperature uniformity and the temperature difference can be controlled below 1%, improving product quality and qualification rate.

Improve and protect the environment

Induction heating does not produce exhaust gases and smoke such as carbon monoxide, carbon dioxide, sulfur oxides, etc., induction heating machines has small external radiation heat and has low noise.

The working environment of the induction heating machine can be purified, the air environment can be protected, the working conditions of operators can be improved, and the health level can be maintained.

Safe and reliable

Induction heating does not produce open flames, eliminating the possibility of dangerous events such as fires and explosions, and greatly improves safety.

Easy to operate and use

The main body of modern induction heating device is an inverter induction heating power supply with power semiconductor power device as the core structure.

It does not need to be preheated and can be started and shut down at any time. Due to this feature, it is not only easy to use and operate, but also saves time and energy.

The installation site occupies a small area

Modern induction heating power supply has a compact structure. Its composition is almost a modular and standardized component composition. Its mass volume is smaller than that of resistance furnaces and flame furnaces.

The induction heating equipment installation occupies a small area and space. The utilization rate per unit area is small. High, saving space and infrastructure costs.

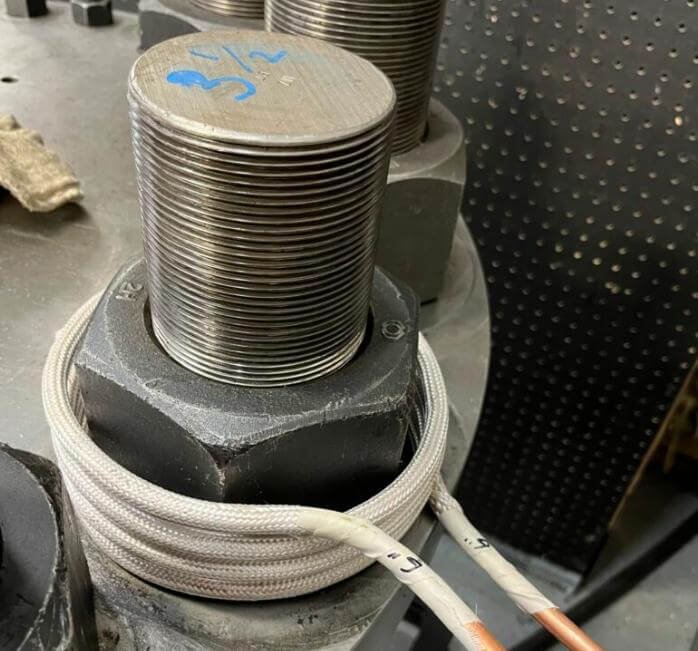

The workpiece can be locally heated

It has greater advantages in heating workpieces with simple shapes, few varieties, and large batches, while it is adaptable to workpieces with small batches and complex shapes.

Heating of workpieces with small batches and large batches has greater advantages, but it is adaptable to workpieces with small batches and complex shapes.

Conclusion

The benefits and advantages of induction heating underline its position as the leading heating technology for modern industrial processes.

From energy efficiency and precise control to fast heating cycles and reduced maintenance, induction heating offers a range of benefits that improve productivity, quality and sustainability across the industry.

As technological advancements continue to refine and expand induction heating capabilities, their importance in shaping the future of manufacturing and materials processing remains undeniable.

Whether you are looking for induction melting furnaces, or accessories/spare parts for induction heating equipment, Kexin Electronic Instrument has what you need.

For more information about our replacement parts for metal-melting furnaces and steel-melting induction furnaces, contact us today.

KEXIN’s induction melting furnace has higher thermal efficiency and lower energy consumption. They can produce a mild metal bath mixture, mixing a uniform alloy at a constant and uniform temperature. For these reasons, this type of furnace is the first choice for induction melting. Kexin products can flexibly meet all customer requirements.

Can we help you?

Whatsapp

Whatsapp