Why Your Induction Heater Isn’t Working: Common Issues Explained?

During the long-term use and operation of induction heating equipment, unexpected issues are inevitable.

To address these effectively, engineers must rely not only on temporary fixes but also on a solid understanding of the equipment’s design and the theoretical principles behind induction heating power systems.

This article highlights common problems that may arise during the daily use of induction heating equipment and offers practical solutions. Let’s explore these issues and how to resolve them.

What should you pay attention to before starting the machine?

After installing an induction heating machine, operators must pay special attention to three key operational concerns: insufficient cooling water supply, high operating voltage, and the grounding capacitance configuration of the equipment.

1. Cooling Water Supply Issues

During continuous and long-term operation, cooling water pipes and internal capacitors may become blocked or scaled due to overheating, potentially leading to capacitor burnout.

This can severely impact the performance of the induction heater. To prevent this, it is essential to monitor the water flow discharge closely. Any sign of abnormal discharge should prompt immediate corrective action to avoid equipment failure.

2. Grounding Capacitance and Insulation Faults

Proper electrical grounding and the condition of the insulation capacitors are critical for safe operation. If the insulation of grounding capacitors is compromised, faults can occur easily.

Engineers should proactively inspect the capacitor box, identify faulty insulation points, and address potential issues before they escalate.

3. High Voltage Concerns

Operating the induction heater at voltages exceeding the rated capacity of its capacitors can lead to frequent breakdowns.

If overvoltage occurs, engineers must quickly reduce the radio frequency or replace the high-voltage capacitors with components rated for higher voltage levels to ensure reliable and safe operation.

What are the main components of the induction heater?

Induction heating equipment primarily comprises three key components: the electrical power supply, the induction heating coil, and the cooling water system.

The power supply is a critical part of the system, typically rated by its output power and operating frequency. Among various types, solid-state inverters are widely used due to their high efficiency.

A typical solid-state inverter consists of two main stages: a rectifier and an inverter. In the rectifier stage, AC line power is converted to DC using diodes or thyristors. This DC is then fed into the inverter stage, where solid-state switches convert it into high-frequency current.

Generally, IGBTs (Insulated Gate Bipolar Transistors) are used for high-power, low-frequency applications, while MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) are suitable for low-power, high-frequency use.

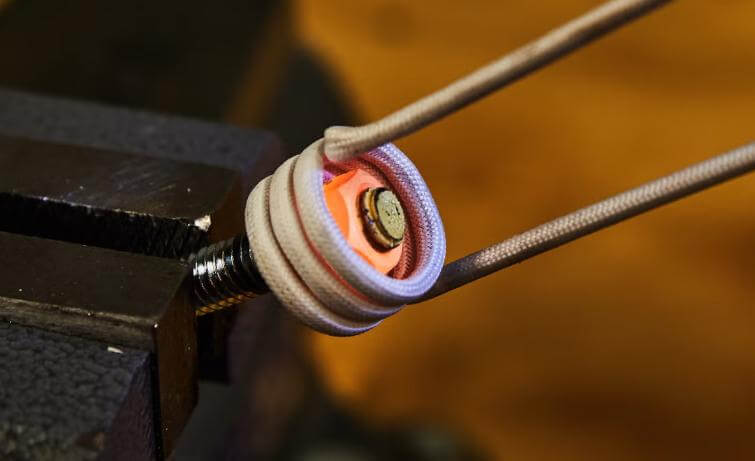

The induction heating coil, usually made of copper tubing or other conductive materials, carries alternating current to generate a variable magnetic field.

Metal workpieces placed inside or near the coil (without direct contact) are heated as eddy currents and hysteresis losses within the metal produce internal friction.

The coil’s material and shape vary depending on the heating application and the type of workpiece.

The cooling water system ensures thermal stability during operation and includes components such as water pipes, soft cables, pumps, cooling towers, and water tanks. To conserve water, most systems use a closed-loop circulation.

It is essential to use clean, dust-free water and to maintain proper maintenance routines. The cooling water should be replaced at least twice a week, and its temperature should be kept below 40°C. Using hot water not only fails to cool the system effectively but can also lead to overheating and other operational issues.

What are some common induction heater problems?

Industrial induction heaters are critical tools across many sectors, but like all equipment, they may encounter operational issues. Below are some common problems, their symptoms, and effective solutions.

1. Inconsistent Heating

Symptoms: Uneven heating of the workpiece, leading to inconsistent hardness or melting.

Causes: Misaligned coils or improper workpiece positioning.

Solutions:

- Ensure the workpiece is properly centered within the induction coil.

- Inspect and adjust coil alignment to evenly surround the workpiece.

- Verify that the power supply delivers stable, non-fluctuating output.

- Use thermal imaging or temperature probes to assess uniformity.

2. Overheating

Symptoms: Equipment feels excessively hot, shuts down unexpectedly, or shows scorch marks/discoloration.

Causes: Inadequate cooling or airflow, excessive input power.

Solutions:

- Regularly inspect and maintain the cooling system, including water flow and fans.

- Ensure proper airflow around the coil and surrounding components.

- Monitor input voltage and current to ensure they remain within the recommended range.

3. Power Issues

Symptoms: Heater fails to start, exhibits intermittent operation, or experiences voltage/current fluctuations.

Causes: Faulty connections, unstable power supply, cable wear or overheating.

Solutions:

- Check all power cables and connections for damage or looseness.

- Measure voltage and current at the input to confirm supply stability.

- Use surge protectors to shield the power supply from electrical spikes.

- Replace any worn or damaged cables.

4. Electrical Noise Interference

Symptoms: Unpredictable heating behavior, shutdowns, or disturbances to nearby electronic equipment.

Causes: Poor grounding or inadequate shielding of electrical components.

Solutions:

- Ensure proper grounding of the induction heater.

- Use shielded cables for power and control lines to reduce electromagnetic interference (EMI).

- Position the heater away from other EMI-generating devices.

5. Coil Damage

Symptoms: Visible cracks or deformities in the coil, reduced heating performance, or abnormal operational noise.

Causes: Physical stress, thermal cycling, or improper handling.

Solutions:

- Conduct routine inspections for signs of wear, damage, or vibration.

- Replace damaged coils promptly to maintain performance and safety.

- Use high-quality coil materials designed to withstand extreme conditions.

- Follow proper handling and installation procedures to avoid mechanical stress.

Enhance the lifespan of the induction heating equipment

Proper maintenance of your induction heater involves more than just addressing issues as they arise—it requires proactive prevention. At Kexin, we are committed to delivering reliable, high-quality service.

Our professionally trained technicians are equipped to handle all types of induction heating challenges, ensuring your equipment operates efficiently and has a longer service life.

To minimize downtime and optimize performance, professionals and engineers working with induction heating systems must undergo continuous training.

In particular, metallurgical process training enhances their ability to diagnose and resolve equipment failures, while deepening their understanding of the behavior and structure of induction systems and their key components.

Kexin offers not only standardized, well-documented procedures and a comprehensive spare parts catalog, but also the essential diagnostic tools needed to identify and resolve induction heater issues quickly and effectively.

KEXIN’s induction melting furnace has higher thermal efficiency and lower energy consumption. They can produce a mild metal bath mixture, mixing a uniform alloy at a constant and uniform temperature. For these reasons, this type of furnace is the first choice for induction melting. Kexin products can flexibly meet all customer requirements.

Can we help you?

Whatsapp

Whatsapp