25KW High Frequency Induction Heating Machine

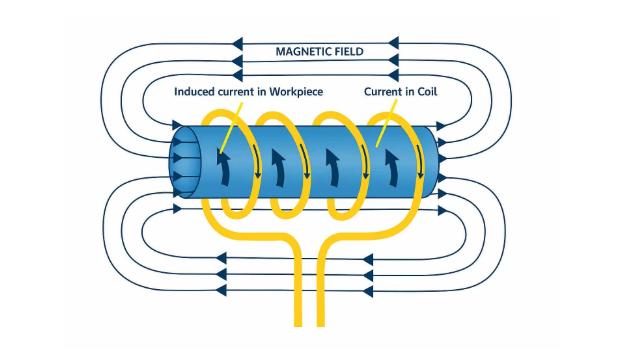

The core of our 25kW high-frequency induction heater lies in its advanced electromagnetic conversion technology. This device converts standard industrial frequency alternating current into a high-frequency alternating magnetic field, utilizing custom-designed copper coils to generate a powerful induction zone.

Model:KX-5188A25S

Rated Power Output:25KW

Frequency Range:30-80KHz

PRODUCT DETAILS

The 25KW high frequency induction heater is a high-performance industrial heating system designed for fast, precise, and energy-efficient metal processing. Also known as a high frequency heating machine or high frequency induction heating power supply, this unit delivers strong and stable 25KW output power, making it ideal for medium to heavy-duty induction heating applications.They can be used in a wide range of applications for metal heat treatment, brazing and smelting.

| 25KW High Frequency Induction Heating Machine (Separated type) | |

| Model | KX-5188A25S |

| Rated Power Output | 25KW |

| Frequency Range | 30-80KHz |

| Single Phase Input | Three Phase 380V/50Hz |

| Current Range | Three Phase 2-35A |

| Volume (mm³) | 670*280*500

500*280*330 |

| Net Weight | 44KG |

| Gross Weight | 55KG |

| Cooling Water Flow | Hydraulic Pressure≧0.2MPa;Flow Rate: 5-20L/Min |

| Cooling Water Temperature | ≤40℃ |

| Water Connection | 1 inlet and 1 outlet |

| Packing Method | Wooden Box |

Our 25KW High Frequency Induction Heating Machine is engineered for speed and thermal efficiency. Unlike traditional furnaces that heat from the outside in, our induction system generates heat inside the metal itself. This is achieved through a combination of the eddy current effect, hysteresis loss, and edge effects, which work together to raise temperatures to the required point in seconds.

Looking for a high-frequency heater that combines German engineering with Japanese precision? Our system uses an all-solid-state semiconductor design to redefine heating efficiency.

German IGBT Technology: The Siemens Infineon IGBT core provides a robust 40-60kHz oscillation, ensuring high stability and a clean, spatter-free environment, critical for high-precision welding and quenching.

Japanese Reliability: With Nichicon (Japan) filter capacitors, our power supply remains ripple-free, extending the lifespan of the machine even in fluctuating power grids.

Multi-National Integrated Circuits: By adopting components from Toshiba, Hitachi, and Motorola, our drive systems offer industry-leading response speeds and fault-tolerant operation.

Smart Automation: Experience full automatic frequency tracking. Our advanced protection circuit provides real-time alerts and clear data visualization, making it the safest and most user-friendly 25KW heater on the market.

The 25KW high frequency induction heater is widely used across multiple industries for fast, precise, and energy-efficient metal processing. Its powerful 25KW output and flexible frequency range make it suitable for a variety of heating, joining, and forming applications.

The 25KW induction heating machine is ideal for metal heat treatment processes, including:

- Surface hardening

- Quenching

- Annealing

- Tempering

Induction heating provides rapid, localized heating with minimal oxidation and deformation, ensuring consistent hardness and improved mechanical performance of metal components.

Thermal Fitting & Shrink Fitting

Thermal fitting uses controlled heating to take advantage of thermal expansion or thermal melting to join components securely. The 25KW high frequency induction heater is widely used for:

- Copper core and aluminum sheet bonding in computer radiators

- Embedded welding of speaker mesh

- Steel-plastic composite pipes

- Aluminum foil sealing (such as toothpaste tubes)

- Motor rotors

- Sealing of electric heating tubes

This process ensures strong, precise, and repeatable connections without mechanical stress.

Metal Melting

The 25KW high frequency induction heater can also be used for metal melting, converting solid metal into liquid through high-temperature induction heating. It is suitable for melting:

- Iron and steel

- Copper and aluminum

- Zinc

- Precious metals such as gold and silver

Induction melting offers fast heating, clean operation, and precise temperature control.

Welding & Brazing

Induction welding and brazing with a 25KW system provide strong joints and high efficiency. Common applications include:

Communication Industry

- Heat sink copper plates

- Antennas

- Cable joints

- RF and radio-frequency wires

- Shaft core terminals

Metal Saw Blade Industry

- Welding and heat treatment of saw blade teeth

- Tungsten carbide drill bits

- Ultra-micro drill bits

Automotive Industry

- Screw hot-pressing and plastic embedding

- Starting capacitors

- Welding of automotive components

Solar Energy Industry

- Solar junction boxes

- Solar bus bars

Electronics Industry

Brazing and welding of tin, aluminum, nickel, silver, and copper components

Forging & Hot Forming

The 25KW High Frequency Induction Heater is well suited for hot forging applications, where workpieces are heated to a controlled temperature before forming. Typical uses include:

- Hot extrusion of watch cases

- Table blanks and handles

- Mold accessories

- Kitchenware and tableware

- Handicrafts

- Standard parts and fasteners

- Mechanical components

- Brass locks, rivets, and steel tools

Induction heating ensures uniform heating, improves material ductility, and increases production efficiency.

Why Choose the 25KW High Frequency System?

Precision Depth Control

Adjusting the frequency optimizes the skin effect, allowing you to switch between shallow surface hardening and deep-penetration red punching or bolt forging.

Superior Surface Quality

The ultra-fast, non-contact heating cycle significantly reduces decarburization and oxidation. For high-end manufacturing, gas protection can be easily integrated but is often unnecessary due to the speed of the process.

Optimized for Small to Medium Parts

The 25KW power rating is the “sweet spot” for heating pipes, plates, and small-volume workpieces with maximum energy utilization.

RELATED QUESTIONS

What is a 25KW High Frequency Induction Heater used for?

A 25KW high frequency induction heater is mainly used for metal heat treatment, brazing, welding, forging, thermal fitting, and metal melting. It is suitable for applications such as surface hardening, quenching, annealing, soldering, and pre-heating before forging.

What materials can be heated with a 25KW induction heater?

This induction heating machine can heat a wide range of conductive metals, including carbon steel, alloy steel, stainless steel, copper, aluminum, brass, and certain precious metals such as gold and silver.

What does 25KW power output mean in practical applications?

A 25KW power rating means the machine delivers strong heating capacity with fast temperature rise and stable performance. It is ideal for medium to heavy-duty industrial applications that require higher efficiency and deeper heat penetration compared to lower-power models.

What is the frequency range of the 25KW high frequency induction heater?

The typical frequency range is 30–80KHz, allowing precise control of heating depth and temperature. Different frequencies can be selected depending on the size, shape, and material of the workpiece.

Is the 25KW induction heater safe to operate?

Yes. High frequency induction heating is a safe and clean heating method. There is no open flame, no direct contact heating, and minimal heat radiation. With proper grounding and water cooling, the system offers reliable and safe operation.

Can the 25KW induction heater be customized?

Yes. Induction coils, output parameters, and system configurations can be customized according to different workpieces and application requirements.

How is the 25KW induction heater packed for shipping?

The machine is packed in a strong wooden box, ensuring safe transportation and protection during domestic and international shipping.

RELATE PRODUCTS

REQUEST A QUOTE

Do you need help with choosing our products?

Fill out this form to get in touch with us.

Whatsapp

Whatsapp