16KW Portable Induction Brazing Machine

The portable induction brazing machine is lightweight and easy to transport, making it ideal for on-site applications or locations where space is limited.

Product Features

Model: KX-16

Rated Power Output: 16KW

Frequency Range: 10-40KHz

Type: Induction Heating Machine

Certification: CE, ISO

Warranty Period: 12 Months

PRODUCT DETAILS

Backed by a team of industrial experts, we offer a huge array of Portable Induction Heater to our clients. These are aesthetically designed and precision-engineered for their higher functionality and durable work life. Moreover, all these Heaters are rigidly tested on various quality parameters to deliver a flawless range at the client’s end.

| Portable Induction Heating Machine | |

| Model | KX-16 |

| Rated Power Output | 16KW |

| Frequency Range | 10-40KHz |

| Main Extension Cable Length | 5m |

| Voltage | 380V+/-10% |

| Frequency | 50/60Hz |

| Rated Current | 19A |

| Maximum Current | 29A |

| Host Size | 280*525*600 |

| Net Weight | 34KG |

| Protection Level | IP42 |

| Packing Method | Wooden Box |

Portable induction heating machine is suitable for industrial heating treatment needs. It is portable and easy to hold and can be widely used for welding different types of pipe fittings. This induction heating machine is more likely to be chosen by pipe fitting manufacturers and suppliers. For example, copper pipes in air conditioners, turning tools in lathes, stainless steel pipes in furniture, etc.

How Does This Portable Induction Brazing Machine Work? equipment

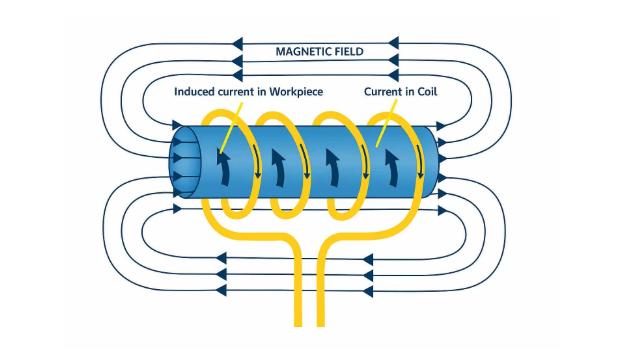

Portable induction brazing machines work by using electromagnetic induction to generate heat in a localized area, which is then used to melt the filler metal (usually the brazing alloy) and bond the two workpieces together.

What Does the Induction Heater Consist of?

The high frequency induction copper brazing machine consists of an electromagnet and an electronic oscillator. It passes high frequency alternating current (AC) through the electromagnet. The rapidly alternating magnetic field penetrates the object and generates currents called eddy currents inside the conductor.

The basic components of an induction heating system are an AC power source, an induction coil, and a workpiece (the material to be heated or processed). Furthermore, the power source sends AC through the coil, which creates a magnetic field. Therefore, when we place the workpiece in the coil, the magnetic field induces eddy currents in the workpiece. The handheld induction brazing machine will produce precise, clean, localized heat without any physical contact between the coil and the workpiece.

Portable Induction Heating Machine Main Components

Control Method: Digital embedded control software

Main Chip: ARM STM32

Chip Speed: 72MHz

Working Mode: Manual mode, automatic mode, and temperature control mode

Current Heating Setting: 5 sections (can be extended to 32)

Number of Working Parameter Storage: 10 pcs/mode

Display Screen: 3.5 inches True Color display screen, resolution ratio 320*240

Communication & Start-up Interface: DB-9 and 4 cores air plug

Bus Access: RS485 (recommended), Profibus (optional), CANbus (optional)

Trial Function Time: 200 hours. (While the trial function enables, the device will be locked down when it reaches the setting time.)

Widely Used in Many Different Applications

KEXIN is a manufacturer of high-quality portable induction heaters for brazing aluminum, brass, copper, copper alloys, iron, cast iron, steel and stainless steel. It provides brazing tools for various important sectors such as automotive, aviation, electronic technology and white goods. This portable induction heater is suitable for hardening parts of automobiles, motorcycles, molds and agricultural machinery.

Some mechanical parts need to be hardened, such as gears and sprockets. In the machine tool hardening industry, such as the bed guides of machine tools, induction heating can provide more precise and cleaner results.

In addition, portable induction heaters can be used for heat treatment of hardware tools. For example, pliers, wrenches, screwdrivers, drills, axes and nails, etc.

KEXIN Portable Induction Heater Machine

What Are the Advantages of Portable Induction Heaters?

- Fast and Efficient Heating: Induction heating is quick, providing rapid heat generation directly at the workpiece, reducing overall processing time compared to traditional heating methods.

- Precision and Control: Portable induction heaters offer precise temperature control, allowing for exact heating of specific areas of the workpiece without affecting surrounding materials, ensuring high-quality results.

- Energy Efficiency: Induction heating is highly energy-efficient because it directly heats the material through electromagnetic fields, minimizing heat loss and reducing energy consumption compared to other heating methods like gas or flame heating.

- Minimal Heat-Affected Zone: Induction heating results in a focused heat source, which minimizes the heat-affected zone, reducing distortion and material damage and preserving the integrity of sensitive workpieces.

- Environmentally Friendly: Without the need for burning fuel or using harmful chemicals, portable induction heaters are cleaner and more environmentally friendly than traditional heating methods, reducing the carbon footprint.

- Reduced Operational Costs: With lower energy consumption, faster processing times, and less maintenance, portable induction heaters can help reduce overall operational costs in the long term.

RELATED QUESTIONS

What materials can be brazed using a portable induction brazing machine?

Portable induction brazing machines can be used on various metals, including steel, copper, brass, aluminum, and their alloys, making them suitable for a wide range of brazing applications.

What is the difference between induction brazing and traditional flame brazing?

Unlike flame brazing, which uses an open flame to heat the workpieces, induction brazing uses electromagnetic induction to heat the material directly. This results in faster, more controlled heating and minimizes the risk of oxidation and contamination.

Can I use a portable induction brazing machine for large-scale production?

While portable induction brazing machines are ideal for smaller, on-site applications or maintenance work, some models can be used for medium-scale production. However, for very large-scale or continuous production, industrial induction brazing systems may be more suitable.

How do I control the temperature with a portable induction brazing machine?

Portable induction brazing machines typically feature adjustable power settings and temperature controls. Some models also offer digital displays and programmable settings for more precise control of heating parameters.

Is the portable induction brazing machine safe to use?

Yes, portable induction brazing machines are safe to use, especially since they do not involve an open flame. However, safety precautions should still be followed, such as wearing protective gear and ensuring proper grounding and electrical safety during operation.

RELATE PRODUCTS

REQUEST A QUOTE

Do you need help with choosing our products?

Fill out this form to get in touch with us.

Whatsapp

Whatsapp