What Are the Advantages and Disadvantages of lnduction Hardening?

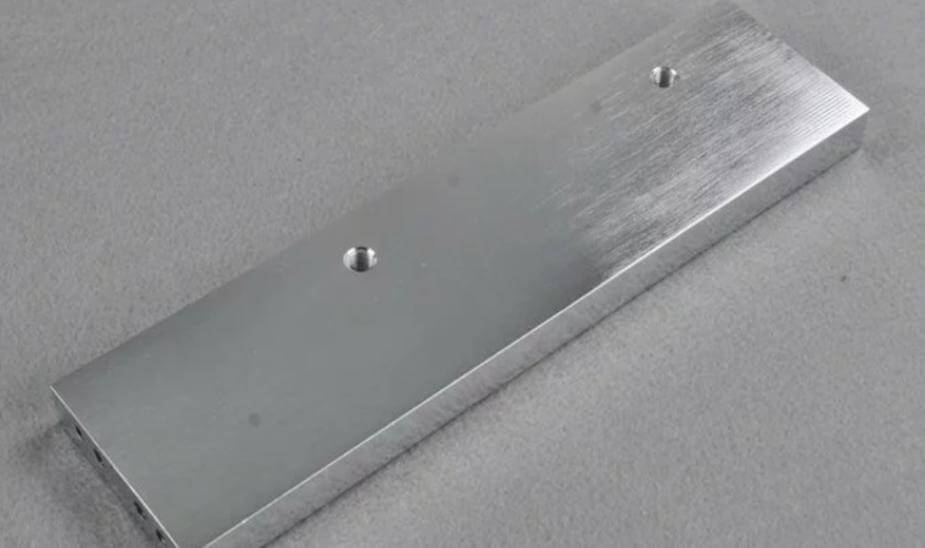

Induction hardening is a heat treatment process popular in the manufacturing industry for its ability to locally harden specific areas of a part.

It’s primarily used to enhance the surface properties of metals, particularly steel, increasing their hardness and wear resistance without affecting other parts of the material. However, like any manufacturing technique, induction hardening has its advantages and disadvantages.

In this blog, we’ll explore these aspects in detail to help you understand the process and determine if it’s suitable for your material.

What is Induction Hardening?

Induction hardening is a surface hardening process in which a metal part is first heated by induction and then quenched. The quenched metal undergoes a martensitic phase transformation, which increases the part’s hardness and reduces its brittleness.

Induction hardening is used to selectively harden certain areas of a part or assembly without affecting the overall performance of the part.

Induction heating is a non-contact heating process that uses the principle of electromagnetic induction to generate heat within the surface layer of a workpiece. When a conductive material is placed in a strong alternating magnetic field, current flows through the material, generating heat due to I²R losses.

For magnetic materials, further heat is generated below the Curie point due to hysteresis losses. The generated current primarily flows through the surface layer, the depth of which depends on the frequency of the alternating magnetic field, the surface power density, the material’s magnetic permeability, the heating time, and the bar diameter or thickness.

By quenching this heated layer in a water-, oil-, or polymer-based quenchant, the surface layer is transformed into a martensitic structure that is harder than the base metal.

Material Choice for Induction Hardening

Commonly used materials for induction hardening include:

- 1045 Steel

- 1141 Steel

- 1144 Steel

- 4140 Steel

- 4340 Steel

- ETD150 Steel

- Cast Irons

How Does Induction Hardening Affect Physical & Mechanical Properties?

Induction Hardening of Steel: Process

Induction hardening is a widely used process for surface hardening steel components. During this process, components are heated using an alternating magnetic field to a temperature within or above the transformation range, followed by immediate quenching.

The core of the component remains unaffected by the treatment, retaining the original physical properties of the material from which it was machined. The surface hardness achieved can range from 37 to 58 HRC.

Carbon and alloy steels with a carbon content in the range of 0.40% to 0.45% are particularly suitable for induction hardening.

How Induction Heating Works?

In induction hardening, a large alternating current flows through a coil, generating a strong and rapidly changing magnetic field within its vicinity.

The workpiece is placed within this magnetic field, where eddy currents are induced in the metal. These eddy currents create resistance, which leads to Joule heating of the material, raising the temperature of the workpiece’s surface to the desired level for hardening.

Induction Hardening for Enhanced Durability

Many mechanical components, such as shafts, gears, and springs, undergo surface treatments after machining to improve their wear resistance. The effectiveness of these treatments depends on both the modification of surface material properties and the introduction of residual stress.

Among various surface treatments, induction hardening is one of the most widely employed methods for improving component durability. The process results in a workpiece with a tough core that has tensile residual stresses, and a hard surface layer with compressive stress.

This combination significantly enhances fatigue life and wear resistance, making induction hardening highly effective for components subjected to high-stress conditions.

Applications of Induction Hardening in Automotive and Machinery

Induction-hardened low-alloyed medium-carbon steels are commonly used in critical automotive and machine applications that require high wear resistance.

The wear behavior of induction-hardened parts is influenced by factors such as the depth of hardening and the magnitude and distribution of residual compressive stress in the surface layer.

These properties play a vital role in improving the longevity and performance of automotive and industrial components.

Benefits of Induction Hardening

1. Cost-Effective Solution

Induction hardening at Kexin offers a cost-efficient alternative to traditional hardening methods. By using lower-cost steel compared to other heat treatment processes, you can significantly reduce your overall production costs without compromising on the quality or performance of the finished product.

2. Minimal Distortion

One of the key benefits of induction hardening is its ability to minimize distortion during the hardening process. Unlike other methods that can cause significant warping or dimensional changes, induction hardening results in minimal deformation, ensuring that the part maintains its original shape and functionality.

3. Enhanced Strength and Fatigue Resistance

Induction hardening enhances the strength and fatigue life of metal components. The process creates a tough, wear-resistant surface while maintaining a softer, more ductile core. This combination of hard surface and resilient core structure improves the overall strength and significantly extends the fatigue life of parts, making them more durable under high-stress conditions.

4. Improved Wear Resistance

For materials that have been annealed or treated to a softer state, induction hardening can greatly enhance wear resistance. By hardening the surface of the workpiece, the material becomes more resistant to abrasion and wear, which is ideal for components subjected to friction or harsh operating conditions.

5. Customizable Hardness with Tempering

After induction hardening, parts can be further tempered to adjust the hardness levels according to specific requirements. Tempering allows for fine-tuning the balance between hardness and brittleness, ensuring optimal performance. A higher degree of tempering results in lower hardness but reduced brittleness, offering flexibility in meeting the exact needs of your application.

What Are the Disadvantages of Induction Hardening?

Material Compatibility Restrictions

While induction hardening offers significant cost benefits, it is limited to materials with specific properties. This process is most effective on metals that contain sufficient carbon and other alloying elements to support the martensitic transformation.

Materials that do not meet these requirements may not achieve the desired hardness or other benefits associated with induction hardening.

Potential for Greater Distortion

Although induction hardening is known for minimal distortion, it can sometimes cause more deformation compared to other heat treatment processes.

The distortion typically results from the martensitic transformation that occurs during the rapid cooling stage of the hardening process. This can lead to dimensional changes that may affect the part’s functionality, especially in intricate or complex geometries.

Risk of Cracking

One of the primary disadvantages of induction hardening is the increased risk of surface cracking. The process can make metal parts more prone to cracking, particularly when compared to other heat treatments.

Additionally, induction hardening can create localized “hot spots” at features like keyways, grooves, cross holes, and threads, which may exacerbate the likelihood of cracks forming in these areas. Careful process control is needed to mitigate this risk.

Conclusion

Induction hardening is particularly recommended when enhanced mechanical properties are needed. It’s ideal for applications requiring improved wear resistance, heat resistance, adhesion, and acid resistance. Kexin specialises in providing first-class induction hardening services to meet the needs of a wide range of industries.

Whether you need small-scale prototyping or high-volume production, we offer customised heat treatment solutions to enhance the performance and durability of your components. Contact us today to learn more about our heat treatment services.

KEXIN’s induction melting furnace has higher thermal efficiency and lower energy consumption. They can produce a mild metal bath mixture, mixing a uniform alloy at a constant and uniform temperature. For these reasons, this type of furnace is the first choice for induction melting. Kexin products can flexibly meet all customer requirements.

Can we help you?

Whatsapp

Whatsapp