lmportance Of Induction Heaters For Green Technology

In today’s rapidly evolving world, promoting green technologies and sustainable practices is more important than ever.

Globally, industries are striving to reduce their carbon footprint and adopt cleaner, more energy-efficient production methods. Induction heating not only improves efficiency but also aligns perfectly with the green technology movement.

What is Induction Heating?

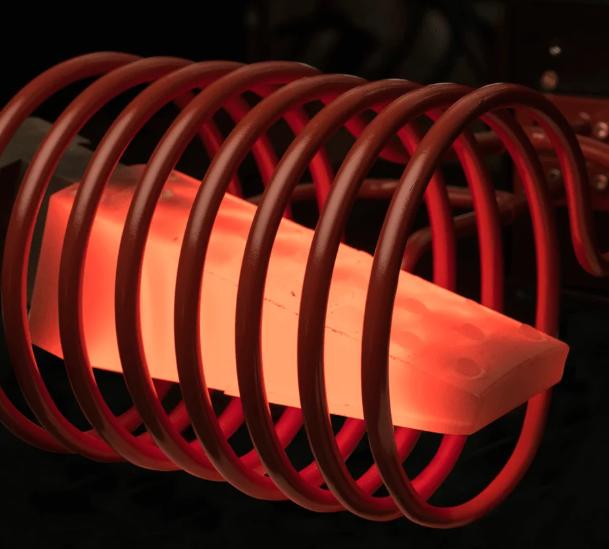

Induction heating is the process of heating electrically conductive materials, namely metals or semi-conductors, by electromagnetic induction, through heat transfer passing through an inductor that creates an electromagnetic field within the coil to heat up and possibly melt steel, copper, brass, graphite, gold, silver, aluminum, or carbide.

An important feature of the induction heating process is that the heat is generated inside the object itself, instead of by an external heat source via heat conduction.

Thus objects can be heated very rapidly. In addition, there need not be any external contact, which can be important where contamination is an issue.

Induction heating is used in many industrial processes, such as heat treatment in metallurgy, Czochralski crystal growth and zone refining used in the semiconductor industry, and to melt refractory metals that require very high temperatures.

How does Induction heating work?

Induction heating is a non-contact method of heating a conductive body by utilizing a strong magnetic field.

Supply (mains) frequency 50 Hz or 60 Hz induction heaters incorporate a coil directly fed from the electricity supply, typically for lower power industrial applications where lower surface temperatures are required. Some specialist induction heaters operate at 400 Hz, the Aerospace power frequency.

Induction heating should not be confused with induction cooking, as the two heating systems are mostly very physically different from each other.

Notably, induction heating systems work by applying an alternating magnetic field to a ferrous material to induce an alternating current in the material, so exciting the atoms in the material heating it up.

Why is an Induction Green Technology?

Induction heating has been around for a while and is by no means a new concept; it is a green technology. It does not depend on fossil fuels, nor does it create any hazardous emissions or carbon dioxide (CO2).

In contrast to gas heating systems, induction offers a cleaner, safer, and more comfortable work environment. When compared to torch heating, induction is flameless, meaning less heat is introduced into the workplace.

Induction heating is better for both employees and the environment. In addition to the environmental benefits, induction heating provides a series of benefits to employees and businesses, as it prevents smoke, waste heat, noxious emissions, and loud noise. Numerous emission-producing processes can be converted to induction heating, such as:

- Flame preheating

- Flame melting

- Flame shrink fitting

- Flame hardening

- Flame brazing

- Flame shrink fitting

- Gas-fired oven heating

- Welding torches for joining

The advantages of induction heating

Reduced Cost

There are many ways that induction heating removes unnecessary costs and saves energy. When using a gas torch, customers can pay more to replace gas tanks as well as the servicing costs. With induction heat, you only need to pay for replacement coils, which last over 200 uses and are less expensive.

You can also salvage parts that would otherwise be discarded because induction heat does not damage the metals. Additionally, induction heating users save more on insurance, on average 10-30%.

Quality Precision

With the ability to fit into tight spaces or difficult angles and to centralize your heat source, you can provide constant, local contact. One of the questions we get asked is whether induction heating is more efficient than other heating methods. The short answer is yes!

This heat is consistent and covers the entirety of your part or application source. With induction heat, you are able to avoid uneven heating and inconsistent results that are common with an oxy-acetylene gas torch.

Increased Productivity and Process Efficiency

You can immediately begin using induction heat in the workplace to improve quality and yield better performance because our products are easy to use. You also will not have to remove or cover other flammable or combustible materials because there is no open flame.

Reduced Damage & Injury Risk

Induction heat produces localized heat which focuses on one part, not a larger area you would get with a torch. This targeted heat reduces collateral damage to adjacent parts or plastic. It also removes the risk of igniting flammable material that can lead to property damage. Induction heat also reduces the risk of injury (such as burns) and damage to your tools.

Induction Heating is More Efficient

Induction is an energy-efficient heating process that converts 70-90% of the consumed energy into useful heat. In contrast to electric ovens, which are typically only 45% energy efficient, the overall efficiency of induction heating is up to two times greater.

Moreover, gas oven efficiency is only around 25-30% energy efficient, which comparatively makes induction three times more efficient, especially considering that start-up and shutdown heat losses are eliminated as induction requires no warm-up or cool-down cycle.

The repeatability and consistency of the induction heating process make it highly compatible with energy-efficient automated systems.

Conclusion

Induction heating not only maintains quality but also improves productivity. Rapid heat transfer reduces processing times, meeting industry demands for efficiency without compromising component integrity. This not only ensures timely deliveries but also contributes to energy savings.

Choosing induction heating is a smart move for manufacturers eyeing growth. It’s like giving your industry a boost—saving energy, cutting waste, and keeping things eco-friendly.

With induction heating, your business doesn’t just survive; it thrives in a greener and more efficient future. Kexin Electronics works round the clock to guide manufacturers in making smart choices.

For more information or to get a quote, give us a call or visit our website at https://www.hfinductionheater.com/

KEXIN’s induction melting furnace has higher thermal efficiency and lower energy consumption. They can produce a mild metal bath mixture, mixing a uniform alloy at a constant and uniform temperature. For these reasons, this type of furnace is the first choice for induction melting. Kexin products can flexibly meet all customer requirements.

Can we help you?

Whatsapp

Whatsapp