Factors To Consider When Selecting a Silver Melting Induction Furnace

With its stunning beauty and valuable properties, silver holds a vital position in numerous industries, especially in jewelry making and electrical component manufacturing.

However, in order to transform silver into desired forms, such as molds, ingots, or intricate jewelry pieces, it must undergo a crucial process called induction melting.

In the following article, we are going to delve into the world of induction melting of silver, exploring its process, benefits, and the equipment involved. Let’s discover the remarkable efficiency and versatility of induction melting in the realm of silver.

Understanding Induction Melting Furnace

An induction furnace is an electrical furnace in which the heat is applied by induction heating of metal. The advantage of the induction furnace is a clean, energy-efficient and well-controlled melting process, compared to most other means of metal melting.

Induction furnaces do not require an arc, as in an electric arc furnace, or combustion, as in a blast furnace. As a result, the temperature of the charge is no higher than required to melt it; this can prevent the loss of valuable alloying elements.

How does a Melting Furnace work?

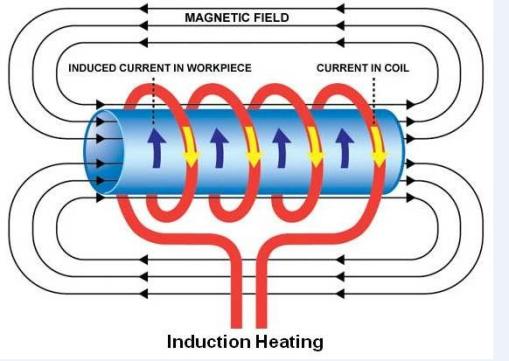

An induction furnace uses electromagnetic induction to efficiently melt metal. It features a non-conductive crucible that holds the metal, surrounded by a copper coil carrying a high-frequency alternating current. This current creates a rapidly changing magnetic field, which penetrates the metal.

The magnetic field induces eddy currents within the metal, generating heat through electrical resistance (Joule heating).

In ferromagnetic metals like iron, additional heat is produced through magnetic hysteresis. As the metal melts, the eddy currents also cause vigorous stirring, promoting uniform mixing of the molten material.

Advantages of Melting Silver Using Induction

Adaptability to Different Silver Alloys

Induction Silver furnaces are specifically designed to handle a wide range of silver alloys. Whether it involves sterling silver, fine silver, or specialized alloys, the induction melting process can accommodate the specific melting requirements of each alloy.

This adaptability allows for versatility in production, catering to diverse industry needs.

Precise Temperature Control

Induction furnaces designed for melting silver offer precise temperature control. Operators have the ability to adjust the frequency and power input, enabling them to maintain optimal melting conditions. This precise temperature control ensures consistent quality and purity of the molten silver, meeting the specific requirements of different applications.

Energy Efficiency

Induction melting showcases remarkable energy efficiency compared to traditional methods. By utilizing electromagnetic induction, the direct heating of silver minimizes energy loss and maximizes the conversion of electrical energy into heat. This results in efficient utilization of resources and reduced energy costs.

Speed and Productivity

Induction melting is synonymous with high melting rates, resulting in faster processing times and increased productivity. The rapid and uniform heating of the silver material allows for efficient production across various industries.

This accelerated melting process enables manufacturers to meet tight deadlines and fulfill customer demands promptly.

Cost-effectiveness

Induction melting offers cost advantages compared to traditional melting methods. The energy efficiency of induction melting reduces energy consumption, resulting in lower energy costs.

Additionally, the precise temperature control and faster processing times contribute to increased productivity, optimising resources and minimising operational expenses.

Applications of Induction Melting of Silver

Jewelry Industry

Induction melting plays a pivotal role in the production of silver jewelry. From casting intricate designs to creating personalized pieces, the efficiency and versatility of induction melting enable jewelry manufacturers to bring their creative visions to life.

Manufacturing Sector

The induction melting of silver finds extensive applications across various manufacturing sectors. From silverware production to electrical component manufacturing and silver-based industrial applications, industries benefit from the speed, precision, and adaptability offered by induction melting.

How to choose a silver melting induction furnace?

Volume of Production

One important factor to consider when choosing an induction furnace for silver melting is your production volume. How large is your output? Equipment and furnace sizes vary. The choice depends on the amount of silver you plan to melt.

Compared to someone with a medium-sized or small design studio, you may need a more powerful furnace for large production runs.

If you have a large manufacturing operation, choosing a smaller furnace can be a costly business decision, impacting your production and returns. Similarly, if your production runs are small, choosing a large furnace will waste heat and money.

Melting Speed

The speed at which a furnace melts metal is crucial because it affects the production volume. The faster the melting rate, the greater the desired production volume.

Therefore, it’s crucial to find a furnace with a high maximum temperature, as silver requires high temperatures to begin melting.

Furnaces with high maximum temperatures melt silver more easily and in a shorter time than furnaces with lower temperatures. When melting large quantities of silver, you need a furnace that can do so in the shortest possible time.

The Price and Budget

The price is another consideration when selecting a silver melting induction furnace. Most silver melting equipment is affordable and works as efficiently as it should.

When you have a budget, it will be easier to pick a furnace that fits the budget and has the right features. The best way to ensure you get something quality within your budget is to compare the prices of various suppliers.

Conclusion

The efficiency, precision, and adaptability of induction melting make it the preferred method across various industries. With the utilisation of induction furnaces for melting silver, manufacturers can achieve high-quality molten silver while optimising energy consumption and production speed.

From the jewelry industry to manufacturing sectors, the versatility of induction melting unlocks the creation of stunning silver products.

Embrace the efficiency and versatility of induction melting of silver to unlock a world of possibilities in your silver melting processes.

KEXIN’s induction melting furnace has higher thermal efficiency and lower energy consumption. They can produce a mild metal bath mixture, mixing a uniform alloy at a constant and uniform temperature. For these reasons, this type of furnace is the first choice for induction melting. Kexin products can flexibly meet all customer requirements.

Can we help you?

Whatsapp

Whatsapp