What You Need To Know About High-Frequency Welding Machines

If you are in the market for a high-frequency welder, there are a few things you should know. In this blog post, we will explore the different types of high-frequency welders, their advantages and what to look out for when buying them.

What are high-frequency welding machines?

The high-frequency welding machine is a versatile and powerful tool. It is a welding machine that uses high-frequency waves to heat the material to be joined. These machines are used in a variety of industries, including automobiles, aerospace, and electronics.

high-frequency welders are designed to weld materials of varying thickness and hardness, making them versatile tools suitable for many different applications.

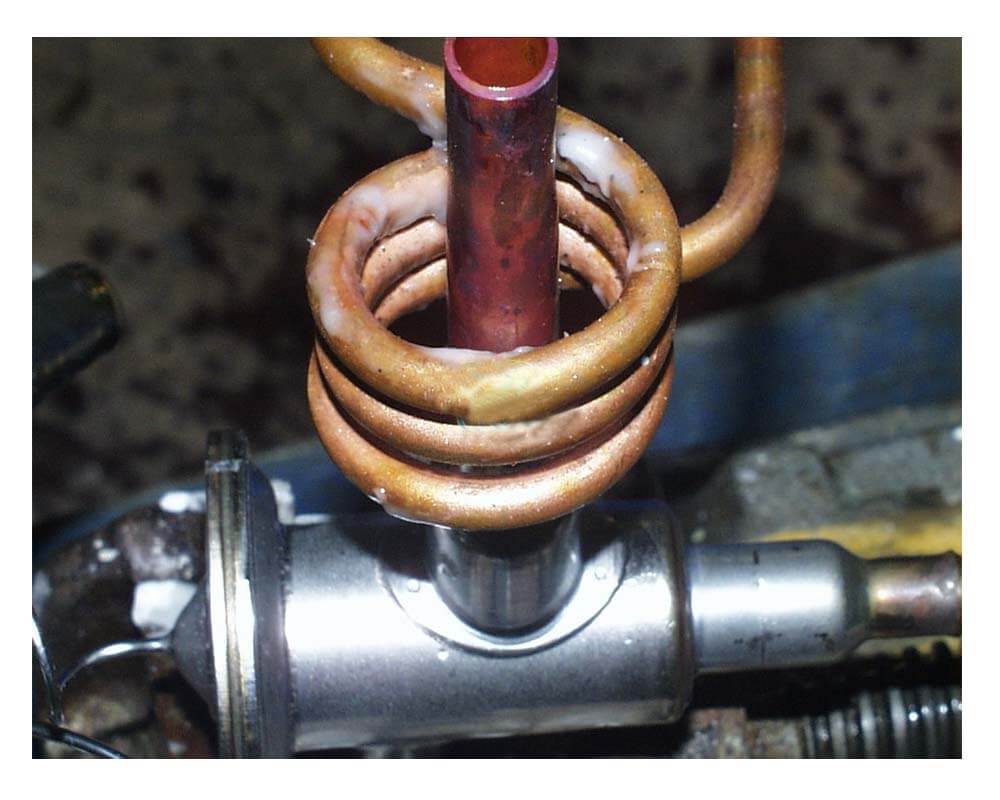

The high-frequency waves used by these machines are generated by electrodes placed on the workpiece. The electrodes emit high-frequency waves that pass through the workpiece and heat it up. When the workpiece is heated, it melts and forms a weld.

The types of high-frequency welding machines

The high-frequency welding machine is divided into spot welding machine, seam welding machine, and welding machine three. Each type of machine has its own advantages and disadvantages, so it is important to choose the right machine for your specific welding needs.

Spot welders are best for small, delicate projects. Seam welders are best for projects that require continuous weldings, such as pipes or pipes. The pair welder is best suited for projects requiring firm flat welding, such as metal plates.

How do high-frequency welding machines work?

High-frequency welders use high-frequency waves to heat and weld two pieces of metal together. The process is similar to other welding methods, but high-frequency waves allow for faster and more efficient welding.

High-frequency welders are used in a variety of industries, from automotive to aerospace. These machines can weld different types of metal, including aluminum, stainless steel, and even titanium.

If you are looking for a quick and efficient way to weld two pieces of metal together, a high-frequency welder is a viable way to do it.

What are the benefits of using a high-frequency welding machine?

The high-frequency welding machine is a type of welding machine that uses high-frequency waves to weld metals together. This method of welding is very efficient and can be used to weld metals of all thicknesses. There are many benefits of using a high-frequency welding machine, which include:

- They are faster than other types of welding machines

- They can weld metals of all thicknesses

- They are very efficient

- They create a strong weld

- They are easier to use than other types of welding machines

If you are considering purchasing a high-frequency welding machine, it is important to weigh all of the potential benefits before making your decision. This guide will provide you with information on the top benefits of using a high-frequency welding machine so that you can make an informed decision.

How to choose the right high-frequency welding machine for your business?

The high-frequency welding process is a commonly used welding method that relies on a high-frequency electromagnetic field to heat the welding area. This type of welding is often used to join thin metal sheets, for example in the automotive industry.

There are several factors you need to consider when choosing a high-frequency welding machine for your business. The first is the material you will be soldering. Different materials require different wattages to weld properly. You also need to consider the thickness of the material and the desired speed of the welding process.

Another important factor to consider is the duty cycle of the machine. The duty cycle is the amount of time the machine can be used continuously before it needs to be shut down to cool down. If you plan to use the machine for extended periods of time, you will need to choose a model with a higher weight capacity.

Some applications of high-frequency welding

High-frequency welding is a type of welding that uses high-frequency waves to heat the metal. This type of welding is often used for thin metals, such as those used in the electronics industry. High-frequency welding has several advantages over other types of welding, including faster welding speed, less heat distortion, and cooler temperatures.

Conclusion

High-frequency welding machines are an important part of the manufacturing process in all walks of life. They are used to weld materials of different thicknesses and properties together and are capable of producing high-quality welds. If you have any questions about it, please feel free to contact us via nancy-sales@foxmail.com.

KEXIN’s induction melting furnace has higher thermal efficiency and lower energy consumption. They can produce a mild metal bath mixture, mixing a uniform alloy at a constant and uniform temperature. For these reasons, this type of furnace is the first choice for induction melting. Kexin products can flexibly meet all customer requirements.

Can we help you?

Whatsapp

Whatsapp