25KW Portable Induction Brazing Machine

The 25KW portable induction brazing machine is designed for efficient and precise brazing of various metal materials.

Product Features

Model: KX-25

High Power Output (25KW)

Portable and Compact Design

Precise Temperature Control

User-Friendly Interface

Induction Heating Efficiency

Cost-Effective

PRODUCT DETAILS

Backed by a team of industrial experts, we offer a huge array of Portable Induction Heater to our clients. These are aesthetically designed and precision-engineered for their higher functionality and durable work life. Moreover, all these Heaters are rigidly tested on various quality parameters to deliver a flawless range at the client’s end.

| 25KW Portable Induction Brazing Machine | |

| Model | KX-25 |

| Rated Power Output | 25KW |

| Frequency Range | 10-40KHz |

| Main Extension Cable Length | 5m |

| Voltage | 380V+/-10% |

| Frequency | 50/60Hz |

| Rated Current | 19A |

| Maximum Current | 29A |

| Host Size | 280*525*600 |

| Net Weight | 34KG |

| Protection Level | IP42 |

| Packing Method | Wooden Box |

The portable induction heating machine is ideal for industrial heating applications, particularly for welding various types of pipe fittings. It is highly favored by manufacturers and suppliers in industries such as air conditioning (copper pipes), machining (turning tools), and furniture (stainless steel pipes). Known for its portability and ease of use, this induction heating machine offers several advantages, including improved product quality, extended product lifespan, and reduced energy consumption.

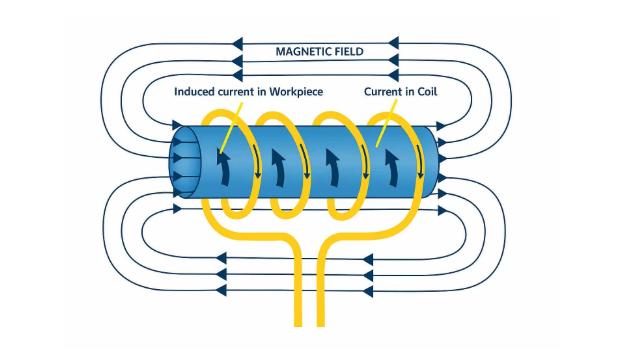

How Does This Portable Induction Brazing Machine Works?

Portable induction brazing equipment is a process that uses electromagnetic induction to heat an electrically conductive object (usually metal) without the need for a flame or direct heat source, by heat generated by eddy currents in the object.

What Does The Portable Induction Brazing Machine Consists of?

Portable induction brazing machines consist of several important components that work together to provide efficient, precise heating for brazing applications. These components are designed to make the machine compact, portable, and effective for field work. The main components include:

Induction Coil: The induction coil is made of copper and generates an electromagnetic field when high-frequency alternating current (AC) is passed through it. The shape and size of the coil is determined based on the workpiece to ensure that heat is applied precisely to the area of the joint that needs to be brazed.

Power Supply: The power supply provides the electrical energy required to generate the high-frequency current to power the induction coil. The power supply is usually compact and integrated into a portable design, allowing the machine to be used in a variety of locations. The power supply also contains a control system that regulates the output power and frequency.

Cooling System: The cooling system is essential to prevent the induction coil and power supply from overheating. It usually uses a water-cooling or air-cooling system to circulate coolant around the coil and other components to maintain the optimal operating temperature during use.

Control Panel: The control panel allows the user to set and monitor important parameters such as temperature, power level, and heating time. Some portable induction brazing machines may be equipped with a digital display to increase control precision and accuracy.

Workpiece Clamp: The clamp holds the workpiece during brazing, ensuring it remains stable during heating. The clamp is adjustable to accommodate workpieces of different sizes and shapes.

Handheld or Portable Design: Unlike fixed induction heaters, portable induction brazing machines are designed to be lightweight and easy to transport. This feature makes them ideal for field jobs that require high mobility.

Braze Material Storage: Some machines may have a dedicated storage room or rack for storing brazing material (filler metal) to ensure it is always available when needed.

Safety Features: Portable induction brazing machines usually have safety features such as overheat protection, short circuit protection, and grounding to prevent accidents and ensure safe operation in various working environments.

Portable Induction Heating Machine Main Parts

Control Method: Digital embedded control software.

Main Chip: ARM STM32.

Chip Speed: 72MHz

Working Mode: Manual mode, automatic mode, and temperature control mode.

Current Heating Setting: 5 sections (can be extended to 32).

Working Status Display Content: Time, current, frequency, current curve

Alarm Interface: Over-current, over-voltage, under water, under pressure, lack of phase, overheating etc.

Communication and Start-up Interface: DB-9 and 4 cores air plug Bus access: RS485 (recommended), Profibus (optional), CANbus (optional)

Trial Function Time: 200 hours. (When the trial function enables, the device will be locked down when it reaches the setting time.)

Memory Card Type: Industrial grade SD card (stored for more than 360 days of processing data and alarm data) (matching function). Need to be purchased separately.

Data Analysis Software: Windows under the installation and operation, with processing data contrast, search for specific processing parameters and alarm parameters and other functions (need to be purchased separately)

Output Power Rating: 18KW

Output Maximum Power: 25KW

Frequency Range: 10-40 KHz

Main Extension Cable Length: 5m

Voltage: 380V +/-10%

Frequency: 50/60 Hz

Rated Current: 29A

Maximum Apparent Power: 26.3KVA

Minimum Fault Container: 3P-63A

Cable Length: 2m

Power Cable System: 3L+PE

Recommended L Cable: 3*6mm²

Cooling Water Flow: 12.5 l/min (17 l/min)

Cooling Water Inlet Maximum Water Temperature: 35℃

Water Pressure Min/max: 4/6 bar

PH Value of Cooling Water: 7.0~9.0

Working Environment Temperature: +5℃ ~ +50℃

Host Form: Box

Host Size: 280*525*600

Weight (including main cable): 34kg

Protection Level: IP 42

Color: Red

Outside Box Size: 370*710*660

Extension Form: Pistol type

Extension Size: 120*280*240

Extension Weight: 5.0kg

Packing Method: Wooden box

Widely Used in Many Different Applications

Kexin is a well-known manufacturer of high-quality portable induction heaters for brazing a wide range of metals, including aluminum, brass, copper, copper alloys, iron, cast iron, steel and stainless steel. The company provides advanced brazing tools for key industries such as automotive, aviation, electronics and white goods.

These portable induction heaters are particularly suitable for hardening automotive and motorcycle parts, molds and dies, and agricultural machinery components. They are ideal for applications such as portable induction silver brazing, handheld induction brazing and induction welding.

Certain mechanical parts, such as gears and sprockets, require hardening, and portable induction heating equipment is an ideal solution for these applications.

In industries such as machine tool hardening (including machine tool bed guides), induction heating provides precise, clean results, ensuring high-quality processing. Induction brazing of aluminum is also very effective in these applications.

In addition, portable induction heaters are ideal for heat treating hardware tools such as pliers, wrenches, screwdrivers, drills, axes and nails, providing reliable and efficient results in a variety of applications.

KEXIN Portable Induction Heater Machine

What Are the Advantages of Portable Induction Heaters?

Portable induction heaters offer a number of key benefits that make them popular in a variety of industrial applications. Here are some of their key benefits:

Portability and mobility: As the name implies, portable induction heaters are lightweight and compact, making them easy to transport and use in different locations. This is especially important for field and field operations that require mobility.

Precise heating control: Portable induction heaters are able to precisely control the heating process, ensuring that the right amount of heat is applied where it is needed. This results in higher quality results, especially for delicate or small parts.

Energy efficiency: Induction heating is efficient because the heat is generated directly within the material, minimizing energy waste. This reduces operating costs and makes the machine more energy-efficient than traditional heating methods.

Clean and safe heating: Induction heating does not require an open flame or external heating source, making it a cleaner and safer process. It reduces the risks associated with flame-based heating methods and ensures a safer working environment.

Faster heating: Induction heating typically heats a workpiece faster than traditional methods, such as gas or electric heating. This can increase production efficiency and reduce downtime.

Reduced wear: The precision and efficiency of induction heating can extend the life of equipment and workpieces because it minimizes the risk of overheating and reduces the mechanical stress that traditional heating methods can cause.

RELATED QUESTIONS

What materials can the 25KW portable induction brazing machine be used on?

The 25KW portable induction brazing machine is suitable for brazing a wide range of materials, including aluminum, brass, copper, copper alloys, steel, cast iron, and stainless steel.

Can this machine be used for both small and large-scale brazing projects?

Yes, the 25KW portable induction brazing machine is versatile enough for both small-scale and larger brazing applications, making it ideal for various industries, including automotive, electronics, and metalworking.

What is the maximum temperature the machine can reach?

The maximum temperature depends on the material being heated, but the machine is capable of reaching the temperatures required for most brazing applications, typically up to 1,000°C (1,832°F).

Can the machine be used for induction hardening or other heat treatments?

While the 25KW portable induction brazing machine is primarily designed for brazing, it can also be used for induction hardening, tempering, and other heat treatment processes, depending on the specific requirements of the material.

RELATE PRODUCTS

REQUEST A QUOTE

Do you need help with choosing our products?

Fill out this form to get in touch with us.

Whatsapp

Whatsapp