The Ultimate Guide to Industrial Induction Heating

Induction heating presents a secure, non-contact, and precise method for elevating the temperature of conductive materials including steel, graphite, copper, brass, silver, gold, aluminum, and carbide. This advanced technology is distinguished by its accelerated heating rates, exact temperature regulation and superior energy efficiency.

Induction heating is a sophisticated process that employs electromagnetic energy and heat transfer via an induction coil to melt materials, thereby generating an electromagnetic field. This technique finds extensive application in various domains including hardening, annealing, tempering, brazing, and soldering.

Industrial induction heating is a critical component across numerous sectors, including automotive manufacturing and metal fabrication. This detailed guide provides an in-depth analysis of the classification of industrial induction heating, exploring its diverse applications and advantages. Additionally, it offers insightful guidance on selecting the most suitable induction heating equipment for your specific project needs.

Induction heating equipment

Induction heating equipment utilizes cutting-edge technology to instantly heat metal objects to the desired temperature, including melting point. It provides fast, precise heating for a variety of industrial applications.

Induction melting furnaces

Our induction melting furnaces are designed to provide efficient, reliable heat treatment for a variety of applications. With advanced technology and precise control, our furnaces ensure consistent metal melting and casting.

Induction brazing equipment

Our induction brazing equipment is designed to provide efficient, precise brazing for a variety of industries. With advanced technology and reliable performance, our equipment ensures fast heating times and consistent results.

Induction forging equipment

Our induction forging equipment is designed to increase the efficiency and precision of your metal working process. In addition to providing consistent heating and precise control of the forging process, it increases productivity and reduces downtime.

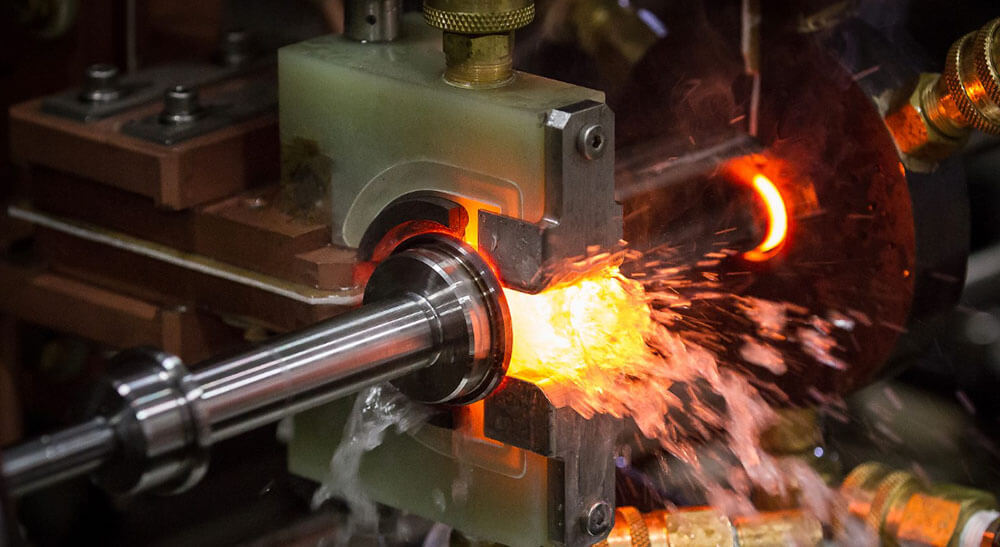

Induction hardening machine

Our induction hardening machines ensure your metal parts are hardened precisely and consistently with advanced technology and precision manufacturing processes.

Induction welding machine

Our induction welders use advanced technology to create strong, reliable welds in seconds. With customizable settings and easy-to-use controls, our induction welders streamline your production process while producing high-quality welded products.

Benefits of induction heating for industries

Energy efficiency

Induction heating stands as a remarkably efficient thermal processing method, delivering an impressive energy transfer efficiency of up to 90%. This represents a 50% enhancement over other conventional heating techniques. Such superior efficiency translates into substantial energy savings when applied to the same quantity of material.

Reduce emissions

Induction heating operates without generating direct emissions, including carbon dioxide or nitrogen oxides. Consequently, it stands as a cleaner and more environmentally sustainable alternative compared to traditional fossil fuel-based heating methods.

Pollution-free

Induction heating neither generates fumes nor emissions, thereby enhancing air quality within the workplace and mitigating the risk of respiratory illnesses among employees.

Reduce noise pollution

Induction heating systems operate with minimal noise, significantly contributing to the reduction of acoustic pollution within both workplace and surrounding environments.

Increase security

Induction heating offers a safe and clean solution by eliminating open flames or hot surfaces, rendering it highly suitable for environments containing flammable materials. This significantly mitigates the risk of accidents and injuries among employees.

Fast heating method

The electromagnetic field produced by the induction heater facilitates rapid material heating and offers swift activation and deactivation capabilities, making it exceptionally suited for applications necessitating quick thermal response.

Portable

Induction heating, which is portable and necessitates solely an induction heater and a power source, significantly simplifies the heating process.

Considerations for Choosing Induction Heating Equipment

When choosing induction heating equipment, there are several important considerations to keep in mind.

These include:

Wattage:

The amount of power needed will depend on the size and type of the workpiece being heated. Make sure to choose equipment with the appropriate wattage to achieve the desired heating results.

Frequency:

The frequency of the induction heating equipment will determine the depth of penetration into the workpiece. Higher frequencies are typically used for smaller parts, while lower frequencies are better suited for larger parts.

Cooling system:

Induction heating equipment generates a significant amount of heat during operation, so it is important to have a reliable cooling system in place to prevent overheating and ensure efficient operation.

Control system:

The control system of the equipment should be user-friendly and intuitive, allowing for easy adjustment of heating parameters and monitoring of the heating process.

Safety features:

Look for induction heating equipment that comes with built-in safety features, such as overcurrent protection and temperature monitoring, to ensure safe operation and prevent any accidents.

Reliability and durability:

Choose equipment from a reputable manufacturer known for producing reliable and durable products. This will ensure that the equipment performs well and lasts for a long time.

Industries That Benefit From Induction Heating

Automotive Industry

Wind Turbine Industry

Aeronautics/Aerospace Industry

Off-Road Vehicle Industry

Oil Country Tubular Goods Industry

Railroad Industry

Hand Tools & Mining Industries

Marine Industry

Construction Industry

Fire Safety/Electrical Conduit Industry

Commercial, Residential & Marine Construction Industries

Power Generation Industry

Fitness & Recreation Industry

Applications of Industrial Induction Heating

Forge heating

Industrial induction heating can be used in the forging industry to heat metal billets or bars to a desired temperature for forging processes. This helps to reduce heating times and improve the overall efficiency of the forging operation.

Heat treatment

Induction heating is commonly used in heat treatment processes such as hardening, tempering, and annealing. It allows for precise control of heating temperatures and heating rates, resulting in consistent and repeatable heat treatment results.

Brazing and soldering

Induction heating is also widely used in brazing and soldering applications, where it provides fast and efficient heating of the joint area without affecting the surrounding materials. This results in stronger and more reliable joints.

Shrink fitting

Induction heating can be used for shrink fitting applications, where a component is heated to expand it and then quickly cooled to allow it to shrink and fit onto another component. This method is commonly used in industries such as automotive and aerospace for assembling parts with tight tolerances.

Metal forming

Induction heating is often used in metal forming processes such as bending, shaping, and extrusion. It allows for localized heating of the metal to soften it and make it more malleable, facilitating the forming process.

Surface hardening

Industrial induction heating can be used for surface hardening applications, where only the surface layer of a component is heated and then rapidly cooled to create a hardened surface. This improves the wear resistance and durability of the component.

Tube and pipe welding

Induction heating is commonly used in the welding of tubes and pipes, where it provides fast and efficient heating of the joint area without affecting the overall structure of the tube or pipe. This results in high-quality welds with minimal distortion.

Metal casting

Induction heating can be used in metal casting processes such as shell molding and investment casting to preheat the molds or patterns, ensuring proper filling and reducing the risk of defects in the castings.

Conclusion

Induction heating represents a secure, non-contact method for the meticulous heating of conductive materials. This precise technique proves highly advantageous in the case hardening of both ferrous and non-ferrous metals. Notably, this process can be executed without any direct contact with the power source.

Selecting the appropriate induction heater is contingent upon your specific application and requirements. An excessively powerful system can lead to increased costs, whereas an insufficiently powered system may impede production efficiency by prolonging the heating process.

Industrial induction heating offers precise and efficient thermal solutions, making it a crucial component of contemporary manufacturing processes. For inquiries regarding the optimal product for your application or customization options tailored to meet your specific requirements, please contact us.

KEXIN’s induction melting furnace has higher thermal efficiency and lower energy consumption. They can produce a mild metal bath mixture, mixing a uniform alloy at a constant and uniform temperature. For these reasons, this type of furnace is the first choice for induction melting. Kexin products can flexibly meet all customer requirements.

Can we help you?

Whatsapp

Whatsapp