35KW Handheld Type High-frequency Induction Brazing Machine

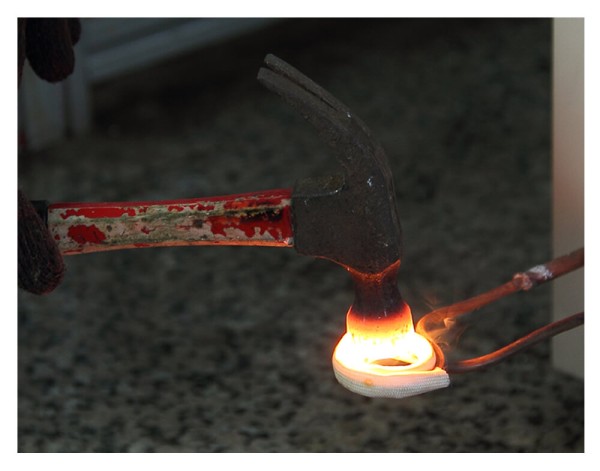

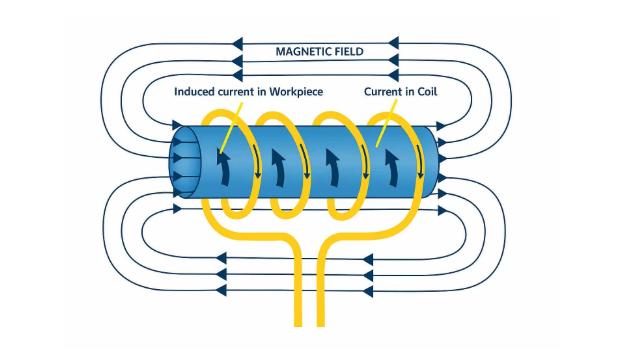

The 35KW High-Frequency Portable Induction Brazing Equipment works by generating high-frequency electromagnetic fields to efficiently heat the workpiece, melt the filler metal, and create strong, durable brazed joints with minimal energy loss and precise control.

Product Features

Model: KX-5188A35P

Power & Frequency

Portability

Cooling System

Fast Heating

PRODUCT DETAILS

Induction brazing is the cleanest and most environmentally friendly heating welding method in the world.

| 35KW Handheld Type High-Frequency Induction Brazing Machine | |

| Model | KX-5188A35P |

| Rated Power Output | 35KW |

| Frequency Range | 30-80KHz |

| Single Phase Input | Three Phase 380V/50Hz |

| Current Range | Three Phase 2-45A |

| Volume (mm³) | 760*310*540 |

| Net Weight | 46KG |

| Gross Weight | 60KG |

| Cooling Water Flow | Hydraulic Pressure≧0.2MPa;Flow Rate: 5-20L/Min |

| Cooling Water Temperature | ≤40℃ |

| Water Connection | 1 Inlet and 1 Outlet |

| Packing Method | Wooden Box |

Induction brazing is commonly employed for brazing materials such as steel, copper and its alloys, stainless steel, high-temperature alloys, and other welded components with symmetrical shapes. It is particularly well-suited for applications involving pipe fittings, pipes, flanges, shafts, sleeves, as well as turning tool heads and sawtooth pieces.

The 35KW high-frequency portable induction brazing equipment is a compact and efficient tool designed for industrial brazing applications. It uses high-frequency induction heating to quickly and accurately melt the filler metal, achieve non-direct contact connection, and ensure clean, consistent and high-quality welded joints. The 35KW high-frequency portable induction brazing equipment operates on the principle of induction heating, which is a method of transferring energy into the workpiece without contact.

Due to the different brazing cross-sectional sizes, the selected frequency band and power are also different. When the welding cross-sectional area of the high-frequency portable induction brazing equipment is less than 30*30mm, a high-frequency induction brazing heater with a frequency of 60~80KHz is generally used. When the welding cross-sectional area is larger than 30*30mm and the processing volume is large, a high-frequency portable induction brazing equipment with a slightly larger power can be selected, with a frequency between 15~60KHZ.

1) Germany SIEMENS INFINEON IGBT Module (40-60KHZ oscillation frequency, fast response time, high arc stability and almost spatter-free welding).

2) Japan Nichicon electrolytic capacitor (filter capacitor).

3) Adopted signal circuit, drive circuit board, control circuit board and components: Toshiba, Hitachi, Motorola and also China’s top manufacturers.

4) International advanced all-solid-state semiconductor power devices.

5) Imported transistor integrated block.

6) High-speed control tube.

7) As with perfect control, protection and alarm display circuit, the machine could get full automatic tracking frequency and continuously adjustable power. It is also safe and dependable protection, clear and occur data display and etc.

High-frequency brazing machines are more versatile than traditional welding machines. Their functions are far more than just welding. In addition to brazing, they can also be used for processes such as hot melting, smelting, heat treatment (such as surface hardening, quenching, annealing and tempering). Welding is just one of its many applications.

The equipment is commonly used for brazing steel, copper and its alloys, stainless steel, high-temperature alloys and other welding parts with symmetrical shapes. It is especially suitable for pipe fittings, pipes and flanges, shafts and sleeves, as well as turning tool heads and serrated parts.

Melting

High-frequency induction brazing machines can be used for melting alloy tools, such as alloy turning tools, milling cutters, planers, saw blades, reamers, boring cutters, etc.

Welding

Various high-frequency induction heating machine treatments for automobile and motorcycle parts, such as crankshafts, connecting rods, piston pins, camshafts, valves, various gears in Kinds of small shaft crank pins, various rocker arms, rocker shafts, and other high-frequency quenching heat treatment.

Forging

Hot forming for all kinds of standard parts, fasteners, machinery parts, hardware tools, and straight shank twist drills. Metal annealing, such as tensile steel; wire, nail wire heating, and stainless steel annealing.

KEXIN 35KW Portable Induction Brazing Equipment

What Are the Advantages of 35KW Portable Induction Brazing Equipment?

Efficient, versatile and precise, the 35KW portable induction brazing equipment offers a range of benefits that make it the first choice for high-quality, cost-effective brazing.

Portability: Its compact and lightweight design makes it easy to transport and use in a variety of locations, including field operations and tight spaces, without compromising performance.

Energy efficiency: The equipment operates with minimal heat loss, ensuring high energy efficiency. This means cost savings and reduced environmental impact compared to traditional brazing methods.

Precise control: Induction heating provides highly localized and controlled heating, allowing for precise temperature management. This minimizes the heat-affected zone and reduces the risk of damage to the workpiece or surrounding areas.

Rapid heating: The high-frequency induction process heats the workpiece quickly, resulting in shorter brazing times and increased productivity. It also allows for faster cooling after the brazing is completed.

High-quality joints: The equipment ensures consistent, high-quality brazing results with strong and durable joints. Precise heat control also ensures that the filler metal is fully melted and evenly distributed.

Versatility: In addition to brazing, the equipment can also be used for other processes such as heat melting, smelting, case hardening, quenching, annealing and tempering, making it a versatile tool for a wide range of industrial applications.

per tube induction brazing equipment; induction brazing process; induction brazing stainless steel; induction brazing aluminum

RELATED QUESTIONS

Is the 35KW portable induction brazing equipment easy to operate?

Yes, it is designed for ease of use, with intuitive controls that allow operators to adjust heating power and frequency for optimal results. Its portability also makes it suitable for both workshop and field applications.

What types of brazing joints are suitable for this equipment?

This equipment is suitable for brazing various joints, especially those that involve symmetrical shapes such as butt joints, lap joints, and T-joints in components like pipes, fittings, and flanges.

How long does it take to braze a joint with this equipment?

Brazing times are generally shorter compared to traditional methods, as the induction process rapidly heats the workpiece. The time will vary based on the size and material of the components being brazed, but the process is typically fast and efficient.

What are the power requirements for the 35KW Portable Induction Brazing Equipment?

This equipment typically requires a power supply that can handle a 35KW output, with specific voltage and frequency requirements based on the model. It also requires a cooling system for optimal operation.

What safety precautions should be taken when using this equipment?

As with any induction heating equipment, users should follow all recommended safety guidelines, including wearing appropriate protective gear, ensuring the work area is clean and free of flammable materials, and using the equipment in accordance with the manufacturer’s instructions to prevent accidents.

RELATE PRODUCTS

REQUEST A QUOTE

Do you need help with choosing our products?

Fill out this form to get in touch with us.

Whatsapp

Whatsapp